What is Material Requirements Planning (MRP)?

Material Requirements Planning (MRP) is a critical tool for manufacturers to effectively manage production scheduling, inventory control, and supply chain planning.

To be more specific, MRP is a system that helps businesses ensure the right materials are available at the right time to meet production demands while minimizing inventory costs and maximizing efficiency.

Today, we are covering key elements of Material Requirements Planning (MRP) and its benefits, as well as the steps involved in implementing an effective MRP system. We also examine how MRP supports modern supply chain management and how to integrate MRP systems with other business systems and processes.

What is Material Requirements Planning (MRP)?

Material Requirements Planning (MRP) is a computerized inventory management system that improves business productivity. The software-based system helps manufacturers plan and schedule the materials and components needed to produce finished goods.

MRP systems calculate the materials needed and when using information from the bill of materials, inventory data, and the master production schedule.

MRP aims to meet three key objectives simultaneously:

- Ensure materials and products are available for production and delivery to customers

- Maintain the lowest possible inventory levels

- Plan manufacturing activities, delivery schedules and purchasing

MRP works by taking inventory of the materials and components on hand, identifying which additional ones are needed, and then scheduling their production or purchase. It uses the bill of materials (BOM), a hierarchical list of all the materials, subassemblies and components needed to make a product, along with their quantities. The demand for materials is dependent on the market for the finished product.

MRP is considered a “push” type production system, where production is based on forecasted demand. This contrasts with “pull” type systems like lean manufacturing, where production is based on actual customer orders. However, some argue MRP can also be used to support lean production.

How MRP Works

Material Requirements Planning is a multi-step process that helps manufacturers determine the quantities of materials and components needed to produce a product and when they are required.

The MRP system uses sales forecasts, current inventory levels, bills of materials, and the master production schedule to calculate material requirements and generate purchase orders to suppliers at the right time. Here is an explanation of the key steps involved in the MRP process:

Taking inventory of on-hand materials and components

The first step in MRP is determining the current inventory levels of raw materials, components, and subassemblies already in stock. The overview provides a starting point for calculating net requirements. The MRP system deducts the inventory from the gross material requirements to determine the net material requirements that must be procured or produced.

Identifying additional materials/components needed

Once the net requirements are determined, the MRP system calculates the additional materials and components needed to meet the production schedule. It uses the bill of materials, which lists all the items that go into making the final product. By checking the bill of materials, MRP determines the gross requirements for each component at each level in the product structure.

Based on the production schedule, MRP calculates when the materials are needed and generates timely purchase orders to suppliers or work orders to the shop floor to ensure materials are available when required. It considers the lead times for each item to determine the appropriate order release dates.

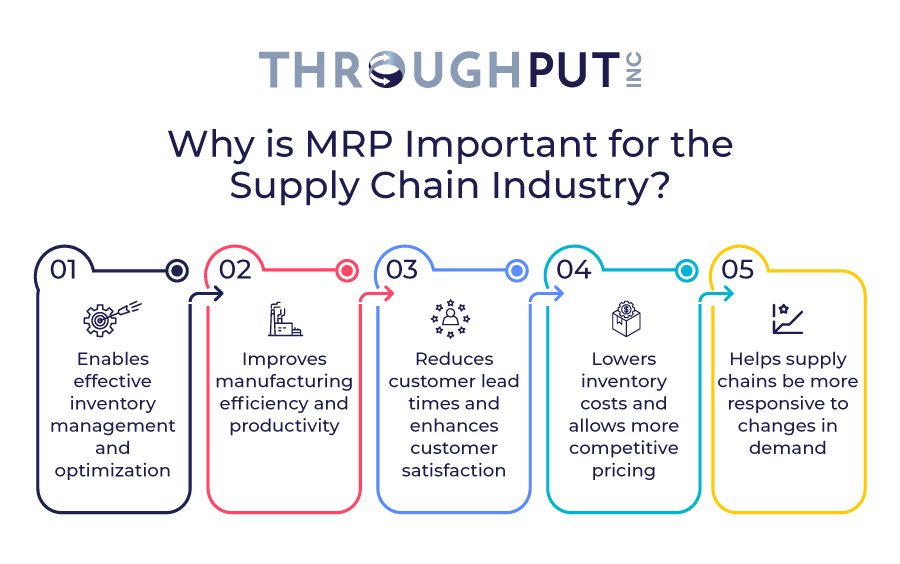

Why is MRP Important for the Supply Chain Industry?

MRP is a critical tool for the supply chain industry because it allows companies to effectively manage inventory, optimize production, and respond to customer demand.

Here are some of the key reasons why MRP is so important.

Enables effective inventory management and optimization

MRP helps companies determine what materials are needed, in what quantities, and when to meet production schedules. By providing visibility into material requirements, MRP allows supply chain managers to optimize inventory levels, reducing the risk of stockouts while avoiding excess inventory that ties up working capital. MRP enables a lean, just-in-time inventory approach

Improves manufacturing efficiency and productivity

With precise material planning from the MRP system, manufacturers can schedule production efficiently, minimizing downtime. MRP ensures the right parts and raw materials are available in the right quantities when needed, improving resource utilization and productivity on the shop floor. Studies have shown that MRP can improve productivity by 30-50%.

Reduces customer lead times and enhances customer satisfaction

MRP helps companies meet customer demand and reduce lead times by optimizing inventory and production schedules. Manufacturers can give customers more accurate delivery commitments since they have advanced knowledge of material availability.

Lowers inventory costs and allows more competitive pricing

MRP promotes leaner inventories by aligning material supplies tightly with production needs. Lower inventory means reduced carrying costs for the business in terms of storage, handling, obsolescence, insurance, and capital costs. These savings can make the company more cost-competitive or be passed on to customers through better pricing.

Helps supply chains be more responsive to changes in demand

MRP systems give supply chain managers the tools and information to adjust quickly to changes in customer demand or market conditions. As new orders come in or demand forecasts change, MRP can help managers rapidly re-plan material requirements, inventory, and production schedules. This agility is increasingly important in today’s fast-paced markets.

What is the difference between MRP and ERP?

The key differences between Material Requirements Planning (MRP) and Enterprise Resource Planning (ERP) systems are scope, purpose, evolution, integration and modules.

Let’s have a look at each of them.

Scope

MRP focuses specifically on manufacturing and production planning. It deals with managing raw materials, components, and production scheduling to optimize manufacturing operations.

ERP has a much broader scope, integrating various business functions like finance, accounting, human resources, sales, marketing, supply chain, and more, in addition to manufacturing. It provides an integrated view of core business processes.

Purpose

The main purpose of MRP is to ensure the right materials are available at the right time for production while minimizing inventory costs. It helps plan manufacturing, purchasing and delivery schedules.

ERP facilitates information flow between all business functions and manages connections to outside stakeholders. It streamlines processes across the entire organization.

Evolution

MRP systems were developed in the 1970s and evolved into Manufacturing Resource Planning (MRP II) in the 1980s with added functionality.

ERP emerged in the 1990s as an extension of MRP II, with added capabilities for accounting, human resources, and other business areas.

Integration

MRP is more of a standalone system focused on manufacturing data and processes.

ERP integrates data from different departments into a single system, enabling data sharing and reducing redundancies. It provides a holistic view of the business.

Modules

MRP includes modules for master scheduling, bill of materials, inventory management, etc.

ERP has a modular and flexible architecture and includes MRP as a module and other modules for finance, HR, CRM, supply chain management, etc.

To sum up, MRP is specific to manufacturing planning and control, while ERP encompasses all integrated management of main business processes across an entire organization. ERP includes MRP as one of its components. Modern ERP systems have evolved to include advanced capabilities like business intelligence, analytics and mobility.

What are the Benefits of Using MRP?

MRP systems offer numerous benefits to organizations, such as streamlining their production processes, optimizing inventory levels, and improving overall operational efficiency.

Here are some extra reasons why companies use MRP systems.

Improved production efficiency and resource utilization

MRP helps organizations optimize their production schedules by ensuring the right materials are available at the right time. MRP synchronizes material availability with production requirements and minimizes production delays and idle time.

MRP also helps identify potential bottlenecks, allowing for proactive measures to prevent disruptions and maintain smooth production flows.

Ability to implement just-in-time (JIT) inventory strategies

MRP enables organizations to adopt JIT inventory management strategies. By accurately calculating material requirements and timing, MRP ensures that materials arrive just when they are needed for production.

The result is less need for excessive inventory holding, as materials are procured and consumed on time. And JIT strategies supported by MRP lead to reduced inventory carrying costs, improved cash flow, and more efficient use of storage space.

Enhanced inventory control and stock-level optimization

MRP provides visibility into current and future inventory requirements. It considers factors such as sales forecasts, production plans, and lead times to determine the optimal stock levels for each material.

Accurate inventory records and dynamically adjusting stock levels based on changing demands are big parts of MRP in practice. Organizations avoid stockouts while minimizing excess inventory, which again leads to reduced working capital tied up in inventory and improved inventory turnover ratios.

Reduction in purchasing costs and carrying costs

MRP enables better coordination between purchasing and production activities. Purchasing departments can consolidate orders, negotiate better prices with suppliers, and optimize order quantities. The main benefit is lower purchasing costs through volume discounts and more favorable terms.

Additionally, by minimizing excess inventory and improving inventory turnover, MRP reduces inventory carrying costs such as storage, insurance, and obsolescence.

Prevention of production bottlenecks and smoother workflows

MRP identifies potential production bottlenecks by highlighting material shortages or capacity constraints. The proactive approach allows organizations to take corrective actions, such as expediting material deliveries or adjusting production schedules, to prevent disruptions.

With a smooth flow of materials and no stockouts, MRP significantly contributes to smoother production workflows – leading to increased throughput, reduced lead times, and improved on-time delivery performance to customers.

Who are the most known MRP providers?

The most well-known MRP providers in 2025 are SAP, Oracle, Microsoft, Infor, and Epicor.

SAP

SAP offers an integrated MRP module as part of its broader ERP system. SAP is one of the largest enterprise software companies in the world and has a significant global presence and market share in the MRP/ERP space.

Oracle

Like SAP, Oracle has a robust MRP module as part of its larger ERP offering. Oracle’s ERP and MRP solutions are used by many large enterprises worldwide.

Microsoft Dynamics 365

Microsoft’s cloud-based ERP system, Dynamics 365, includes MRP capabilities. It has gained significant adoption, leveraging Microsoft’s global reach and integration with other Microsoft products.

Infor

Infor is another major cloud-based ERP solution provider that offers strong MRP functionality and focuses on specific industry verticals.

Epicor

Epicor provides MRP as part of its manufacturing-focused ERP system. They have a significant customer base among midsize and large manufacturers around the world.

A few other notable MRP providers that are popular, especially among small to midsize manufacturers, include:

- Fishbowl Manufacturing

- IQMS

- Sage Business Cloud X3

- NetSuite

- Plex Systems

The MRP software market is quite fragmented, with many other smaller vendors that cater to specific geographies and industry niches. The best fit depends a lot on an organization’s specific requirements, existing systems, budget, and implementation resources.

How do MRP software providers compare in terms of pricing?

The pricing for MRP software varies quite a bit depending on the vendor, including features, deployment model (cloud vs on-premise), and business size. Approximate pricing data points currently look like this:

- SAP Business ByDesign, a cloud ERP with MRP functionality, is priced around $20,000/year

- QAD ERP, which has MRP capabilities, is around $40,000/license for on-premise deployment

- Odoo, an open-source ERP with MRP, starts at just $6/user/month for the cloud version

In general, cloud-based MRP software is priced on a monthly subscription basis per user, while on-premise MRP usually has a larger one-time perpetual license fee. Cloud software tends to be more affordable upfront.

Open-source MRP software like Odoo has very low starting prices compared to proprietary MRP systems from larger vendors like SAP, Oracle, Microsoft, etc. However, open source may have more limited functionality.

MRP systems focused on small businesses tend to be more affordable than enterprise-grade MRP software designed for large manufacturers. Pricing is scaled based on the size and complexity of the business.

Some MRP providers do not publicly release pricing and instead require getting a custom quote based on the specific business requirements and number of users. So, apples-to-apples pricing comparisons can be difficult.

MRP pricing ranges from very affordable starter packages under $100/month to expensive enterprise installations over $100k+.

However, cloud-based MRP subscriptions generally provide the most flexibility and lowest upfront costs compared to traditional on-premise perpetual license models.

Final works on MRP

Material Requirements Planning is critical for effective manufacturing and supply chain management. It enables companies to optimize inventory levels, improve production efficiency, and better meet customer demand.

MRP systems use sales forecasts, inventory data, and the bill of materials to calculate the materials needed and when to support the master production schedule.

MRP helps companies be more responsive and agile. MRP provides an integrated view to drive more informed decision-making by tying together sales, production, and inventory information. When coupled with other systems like ERP, MRP enables even tighter synchronization and optimization across the supply chain.