What is Enterprise Resource Planning (ERP)?

An Enterprise Resource Planning (ERP) system is a suite of integrated software applications that helps organizations manage and automate their core business processes.

An effective ERP manages day-to-day business activities such as accounting, procurement, project management, risk management and compliance, and supply chain operations.

ERP provides a centralized platform for collecting, storing, managing, and interpreting data from various business activities.

This integrated view of core business processes can help companies improve efficiency, cut costs, and respond more nimbly to changing market conditions and customer needs.

In this article, we’ll dive deeper into what ERP software does and the specific benefits it can provide to organizations.

How does ERP Integrate Various Business Functions and Processes?

The central feature of ERP software is a shared database that supports multiple business functions used by different departments.

This means employees in different divisions, such as accounting and sales, can rely on the same information for their needs.

ERP systems facilitate information flow between all business functions and manage connections to outside stakeholders. ERP systems allow data to flow into the centralized database across the organization, and thus eliminate data duplication and provide data integrity with a “single source of truth.”

On-premise vs Cloud-based ERP Deployment Options

ERP systems can be deployed on-premise, where the software is installed and runs on computers on the organization’s premises, or in the cloud, where the software is hosted on the vendor’s servers and accessed through a web browser.

On-premise ERP puts the system in the company’s own data center and on its servers. The company is responsible for the security, availability and overall management of the ERP software and related hardware and software.

Cloud-based ERP, or SaaS, runs on the vendor’s servers in data centers. The vendor manages the software and provides updates and security.

Users access the system through a web browser, making it accessible from anywhere with an internet connection.

Cloud ERP is popular due to lower costs, faster implementation, and more effortless scalability. However, some organizations prefer on-premise deployment for greater control over their ERP system and data.

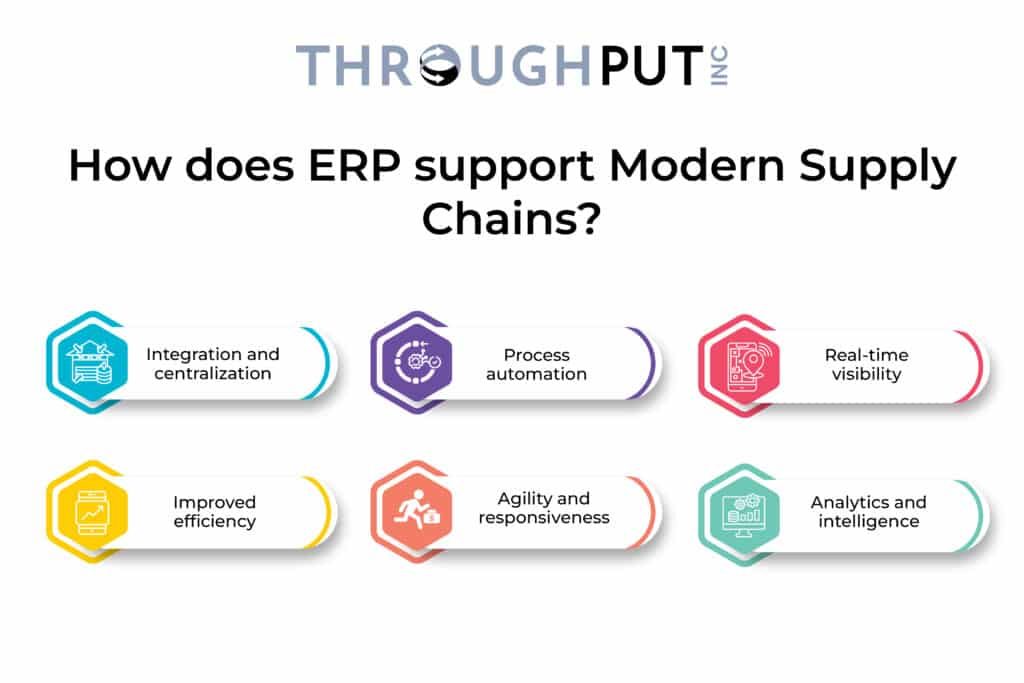

How does ERP support Modern Supply Chains?

ERP supports modern supply chains by managing the complexities and enabling the responsiveness required in today’s fast-paced, global supply chains.

It provides the integration, automation, visibility and intelligence needed to optimize end-to-end supply chain processes and performance.

ERP systems support and enhance modern supply chain management in several key ways:

Integration and centralization

ERP is a central system that integrates various supply chain functions like procurement, inventory management, production planning, order management, logistics, and returns.

This provides a single source of truth and enables better coordination and communication across the supply chain.

Process automation

ERP automates many routine supply chain tasks such as demand forecasting, inventory replenishment, procurement, order processing, and logistics scheduling. This eliminates manual work, improves productivity, and reduces errors.

Real-time visibility

With an integrated ERP, companies gain end-to-end, real-time visibility into inventory levels, order status, shipment tracking, and more. This enables faster decision-making, better customer service, and optimization opportunities.

Improved efficiency

ERP makes the entire supply chain more efficient by automating processes, providing visibility, and enabling collaboration. It can help reduce costs, improve on-time delivery, optimize inventory, and boost overall supply chain performance.

Agility and responsiveness

The centralized data and process integration enabled by ERP makes companies more agile. They can quickly respond to changes in demand, supply disruptions, or new market opportunities.

Analytics and intelligence

Modern ERP systems have embedded analytics that provide insights into supply chain performance, identify bottlenecks, and enable data-driven decision-making and continuous improvement.

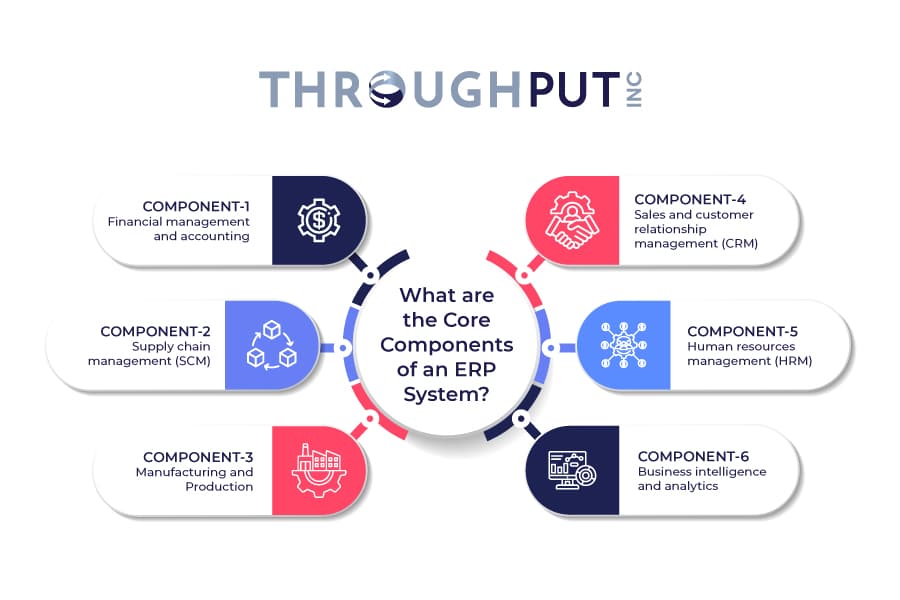

What are the Core Components of an ERP System?

The core components of an ERP system are supply chain management (SCM), financial management and accounting, manufacturing and production, sales and customer relationship management (CRM), human resources management (HRM), and business intelligence and analytics.

The exact terminology and bundling of these modules may vary across ERP vendors; here’s our component overview:

COMPONENT 1: Financial management and accounting

The financial management and accounting module forms the backbone of an ERP system. It streamlines financial operations, providing real-time visibility into an organization’s financial health. Key features include general ledger, accounts payable, accounts receivable, cash management, budgeting, and financial reporting.

This module ensures accurate bookkeeping, faster financial closes, and adherence to financial regulations.

COMPONENT 2: Supply chain management (SCM)

The SCM module optimizes the flow of goods and services, including the movement and storage of raw materials, work-in-process inventory, and finished goods from point of origin to point of consumption.

It encompasses inventory management, purchase order processing, supplier scheduling, and logistics. By integrating with the financial and manufacturing modules, SCM enables better demand forecasting, inventory optimization, and faster time-to-market.

COMPONENT 3: Manufacturing and Production

For manufacturing firms, the production module is crucial. It helps plan, schedule, and track manufacturing operations, ensuring optimal utilization of resources.

Features include bill of materials (BOM) management, work order processing, shop floor control, quality management, and product costing. Integration with the inventory and procurement modules allows efficient material planning and execution.

COMPONENT 4: Sales and customer relationship management (CRM)

The sales and CRM module facilitates the management of customer interactions, sales processes, and marketing efforts. It includes lead and opportunity management, sales forecasting, order management, pricing, and customer service functionalities.

The module provides a 360-degree view of customers, and this in return helps improve sales effectiveness, customer satisfaction, and revenue growth.

COMPONENT 5: Human resources management (HRM)

The HRM module streamlines the management of an organization’s workforce.

It automates core HR processes such as employee information management, recruitment, performance management, training and development, payroll, and benefits administration.

Self-service portals empower employees to access their information and perform routine tasks, reducing the administrative burden on HR staff.

COMPONENT 6: Business intelligence and analytics

Modern ERP systems often include embedded business intelligence and analytics capabilities. These tools enable organizations to gain insights from the vast amounts of data generated across various modules.

With features like dashboards, reporting, and data visualization, decision-makers can monitor key performance indicators (KPIs), identify trends, and make data-driven decisions to optimize operations and drive strategic initiatives.

The integration and interoperability of these core components set an ERP system apart. ERP provides a unified view of an organization’s operations as it breaks down data silos and enables seamless information flow across departments.

This facilitates better coordination, enhances efficiency, and supports informed decision-making.

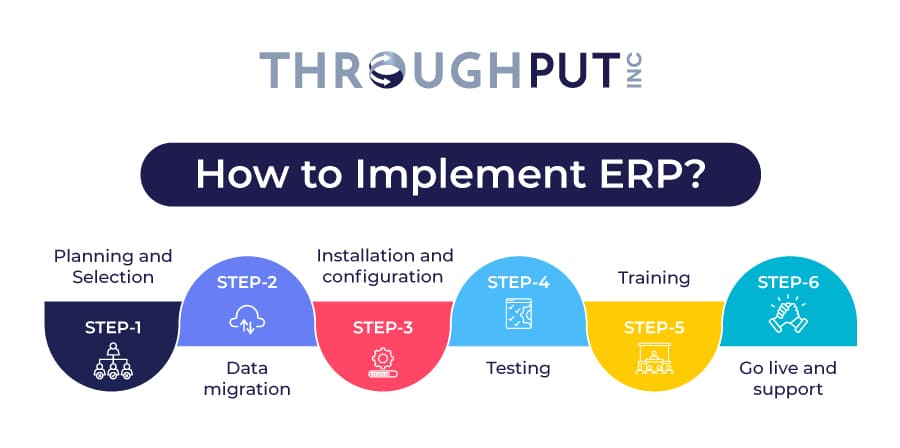

How to Implement ERP?

ERP is implemented in several steps that involve detailed planning, effective data migration, proper system configuration, thorough testing, comprehensive training, and ongoing support and optimization.

The implementation is a complex undertaking that requires careful planning and execution. Here’s a detailed breakdown of each step:

STEP 1: Planning and Selection

The first step is to plan the ERP implementation thoroughly. This planning includes defining clear goals and objectives, determining the scope, establishing a project timeline and budget, and assembling a cross-functional team.

A critical part of this stage is selecting the right ERP software that aligns with the organization’s requirements, industry, and future growth plans.

Factors to consider include functionality, scalability, user-friendliness, vendor support, and total cost of ownership.

STEP 2: Data migration

Data migration is transferring data from legacy systems to the new ERP database. This is a crucial and often challenging phase.

Best practices include cleansing and standardizing data before migration, defining precise data mapping and transformation rules, testing the migrated data thoroughly for accuracy and completeness, and ensuring data security and compliance.

Sufficient time and resources must be allocated for data migration to ensure the overall ERP implementation is on time.

STEP 3: Installation and configuration

Once the ERP software is selected and data migration is underway, the next step is to install and configure the system.

This involves setting up the IT infrastructure, defining user roles and access controls, configuring modules and business processes, and integrating the ERP with other systems if needed.

The ERP should be configured to match the organization’s unique business requirements and workflows.

STEP 4: Testing

Rigorous testing is essential before going live with the new ERP system. This includes unit testing, integration testing, user acceptance testing (UAT), and performance testing.

The goal is to identify and resolve any issues or bugs, validate system functionality and data accuracy, and ensure the ERP performs optimally under real-world conditions. Involving end-users in UAT helps obtain valuable feedback and buy-in.

STEP 5: Training

Comprehensive training is critical for successful ERP adoption. End-users need to understand how to navigate and utilize the new system effectively.

Training should cover ERP fundamentals, specific job-related functions, and best practices. Various training methods, such as classroom sessions, hands-on workshops, video tutorials, and simulations, can be used.

Ongoing support and refresher training should also be provided post-implementation.

STEP 6: Go live and support

After thorough testing and training, the organization is ready for the ERP system to “go-live”. This is often done in phases, starting with a pilot or limited rollout before deploying to the entire organization.

Adequate support must be in place during and after going live, including technical support, help desk, issue resolution, and performance monitoring.

Continuous improvement and optimization efforts should be followed to realize the full benefits of the ERP system over time.

What are the Benefits of Implementing an ERP System?

Implementing an Enterprise Resource Planning (ERP) system can significantly benefit organizations by integrating and automating core business processes. Here are some of the key advantages.

Streamlined processes and increased efficiency

ERP systems integrate various functional areas such as finance, human resources, manufacturing, supply chain, and customer relationship management into a single system.

This eliminates data silos, reduces manual data entry, and automates workflows. ERP improves operational efficiency and productivity across the organization due to streamlining processes and reducing redundancies.

Centralized data and a single source of truth

An ERP system stores data from different departments in a centralized database. This provides a consistent source of information, often called a “single source of truth.”

Centralized data eliminates discrepancies and inconsistencies that often arise with disparate systems. It ensures that everyone in the organization works with accurate, up-to-date information, leading to better collaboration and decision-making.

Improved visibility and real-time information

ERP systems provide real-time visibility into key business metrics and performance indicators. Managers can access dashboards and reports that give them a holistic view of the organization’s operations. Real-time data enables faster identification of issues, bottlenecks, and opportunities. This improved visibility supports proactive decision-making and agile responses to changing business conditions.

Better decision making

ERP systems’ integrated data and analytics capabilities empower managers to make informed, data-driven decisions. ERP provides tools for forecasting, scenario planning, and what-if analysis.

By leveraging the wealth of data captured across the organization, decision-makers can identify trends, optimize resources, and make strategic choices that drive business growth and profitability.

Cost savings

While implementing an ERP system requires an initial investment, it can lead to significant cost savings in the long run. ERP helps reduce operational costs by automating manual processes, minimizing errors and rework, and optimizing inventory levels. It can also help identify areas of waste and inefficiency, enabling organizations to streamline operations and reduce costs.

Scalability to support business growth

ERP systems are designed to be scalable and can support an organization’s growth and changing needs. As a company expands into new markets, adds new product lines, or acquires other businesses, the ERP system can be easily configured to accommodate these changes.

This scalability ensures that the organization’s technology infrastructure can keep pace with its growth without requiring extensive IT overhauls.

What are the Challenges of Implementing an ERP System?

The biggest challenges of implementing an ERP system are significant time and resource investments, change management and user adoption, data security and privacy.

Here are the biggest challenges and most important considerations that organizations must be aware of:

Significant time and resource investment

ERP implementations require substantial time, money, and internal resources.

The costs include software licenses, hardware upgrades, consulting fees, data migration, customization, integration, and training. Organizations must carefully plan and budget for these costs.

The implementation process can also be lengthy, often taking several months to over a year for large, complex organizations. During this time, key personnel may need to be dedicated to the project, removing them from their regular duties.

Organizations must weigh the long-term benefits against the short-term disruption and resource drain.

Change management and user adoption

Implementing an ERP system requires significant changes to business processes and employee roles. Resistance to change can be a major obstacle. Effective change management is critical to ensure user buy-in and adoption.

This includes clear communication about the reasons for the ERP implementation, the benefits it will bring, and how it will impact employees’ day-to-day work.

Extensive training must be provided to help users understand and become proficient with the new system.

With adequate change management and training, organizations can avoid low user adoption, leading to a good return on their ERP investment.

Data security and privacy

ERP systems consolidate sensitive business data in a centralized database, making data security and privacy critical considerations.

Organizations must ensure appropriate controls are in place to protect against unauthorized access, data breaches, and cyber-attacks.

Compliance with data privacy regulations like GDPR must also be addressed. When using cloud-based ERP, organizations must carefully vet the vendor’s security measures and ensure robust service level agreements (SLAs) are in place.

How to Choose the Right ERP Vendor?

To choose the appropriate ERP vendor, it’s essential to conduct a thorough evaluation based on several key criteria.

These include the system’s functionality and how well it aligns with your business needs, the user-friendliness of the interface, the flexibility and customization options it offers, and its ability to integrate with your existing systems.

Additionally, consider the vendor’s stability and proven success in the industry, the cost structure and licensing model of their ERP solution, and the quality of their customer support and maintenance services.

It’s crucial to choose an ERP partner that has a deep understanding of your specific industry and the unique challenges your organization faces.

Conducting comprehensive due diligence before making a decision is vital to ensure a successful ERP implementation and to prevent expensive errors in the future.

Conclusion

Enterprise Resource Planning (ERP) systems are integrated software applications that help organizations manage and automate their core business processes.

ERP systems improve efficiency, decision-making, customer service, and regulatory compliance by providing a centralized data collection and interpretation platform.

Implementing ERP requires careful planning and continuous optimization.

While complex, ERP systems are essential for organizations to innovate and thrive in a digital business environment.