ThroughPut Capacity Planning Software: Optimize Your Capacity Plans With The Power Of AI

The Covid-19 pandemic has reset perspectives, priorities, and strategies across the supply chain industry. Moreover, it has resurfaced the importance of capacity planning and utilization based on the ever-changing demand-supply dynamics.

Supply chain planners are therefore now setting a razor-sharp focus on:

- Optimizing production and distribution capacity across supply chain funnels

- Proactively assessing the exact impact of market fluctuations on operations and analyzing the available resource capacity

- Conducting scenario planning to assess and identify resources for meeting additional sales.

- Signaling risks in a capacity shortage where certain products may not be in actual demand.

At ThroughPut, we have been working towards creating perceptive supply chain solutions that can help tide through these uncertainties with AI-driven proactive intelligence.

In our last release, the ThroughPut Demand Sensing Solution addressed the gaps unveiled by the pandemic and the sudden shift in existing market dynamics.

The Demand Sensing Module is a strong data-driven go-to planning and forecasting tool, to accurately analyze and correlate demand insights and respond to fluctuating margins and inventory needs.

“Demand Sensing is the first step of putting your end-to-end supply chain on autopilot. We hope this new module will ensure that customers never miss out on customer demand again due to operational constraints.”

Ali Raza, Founder & CEO, ThroughPut Inc

In this release, we are launching the ThroughPut Capacity Planning Solution that takes demand planning and sensing one step forward and applies it to executing the forecasted demand. Accurate capacity planning optimization and utilization analysis are now undeniably the most essential tools for a transparent end-to-end supply chain.

By being able to seamlessly evaluate the actual capacity against realized demand, assess scheduled production load of processes over time, and track the inventory built up amid lost sales opportunities, a sound capacity planning solution can help tide over tricky demand-supply scenarios.

Capacity planning directly impacts the ability of a firm to manufacture products in a given period of time. A sound network capacity planning software and utilization plan can help in directing operations towards advanced productivity.

For the demand planners and S&OP teams, effective capacity planning can help drive accurate product-mix decisions amidst the most dynamic demand-supply conditions.

For an operations manager, effective capacity planning can ensure adequate machine utilization to nail down the constraints of the operation where they exist

Overcome Operational Constraints in Real-Time with ThroughPut’s AI-powered Capacity Planning Solution

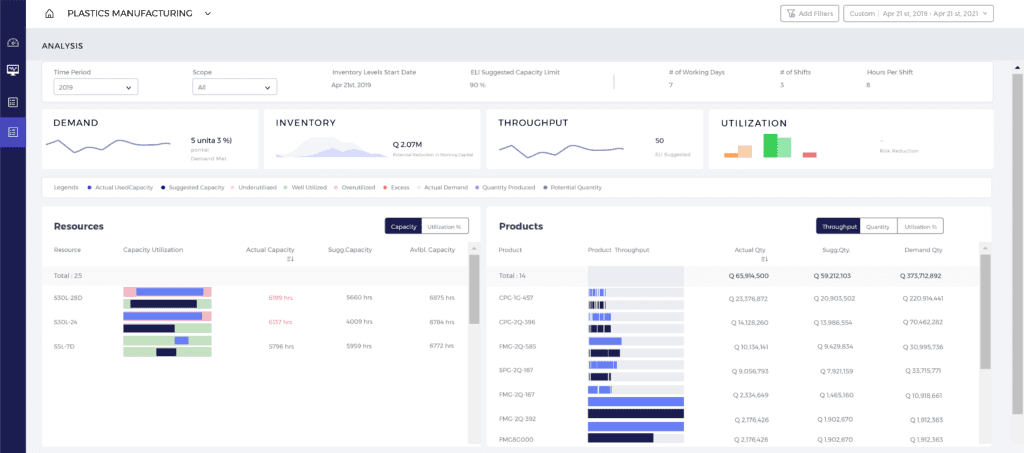

The ThroughPut Capacity Planning Solution gives you the strategic advantage to help free up existing capacity and adequately meet customer demand on time. It ensures sufficient working capital while providing additional throughput potential consistently across various demand-supply scenarios.

With the ThroughPut Capacity Planning Tool, organizations can now leverage the power of AI to proactively meet the below capacity utilization goals:

- Evaluate the actual capacity against realized demand, scheduled production load of processes over time, inventory build-up, and lost sales opportunities.

2. Assess the ability to meet future demand, highlight risks and propose mitigation strategies.

3. Expose which products are affected by internal and external constraints

4. AI-driven prioritizations to schedule limited resources against the product mix optimized for the highest throughput potential.

Manufacturers can minimize throughput losses by maximizing the demand closer to real-time with the need to offset by production lead time. It keeps the resource utilization under the set capacity limit and minimizes operations expenses that tap into the purchase of extra capacity.

Armed with accurate real-time data, ThroughPut replays the past with historical data analysis to plan the near future better to help capacity planners, demand planners, and demand managers leverage capacity plans to the fullest amidst challenging market scenarios such as Covid-19.Get answers to capacity-related questions with ThroughPut:

- Which key assets will be subject to constraints, when and at what frequency?

- What drives the constraints over this period of time?

- How do demand-supply imbalances impact the overall throughput?

- How many shift deviations would possibly occur due to imbalances?

- When to adjust Capacity to balance supply with demand?

- How to decide on the process and facility flexibility?

- Which production line is being wasteful or inefficient by not maximizing the potential output.

- Which resources are over or underutilized for enhanced decision-making regarding ordering and long-term utilization strategy?

Unlocking Asset Performance Management to meet your Capacity Utilization Goals

Our capacity planning software helps with concrete solutions to the above, by unlocking the value to meet your capacity utilization goals:

Boost Asset Performance Management

Asset performance is a key indicator in this release as this helps Capacity Planners, Operations Managers and Chief Supply Chain Officers get a bird’s eye view across the capacity levels.

Accurately estimate the capacity of your asset load and easily plan for scheduled or unscheduled maintenance. Get instant multi-site and multi-plant visibility for work order assignment across assets.

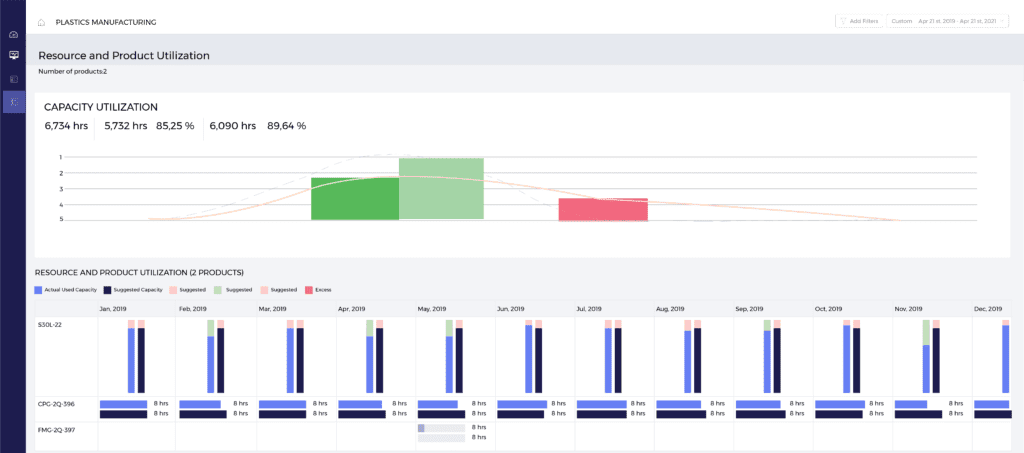

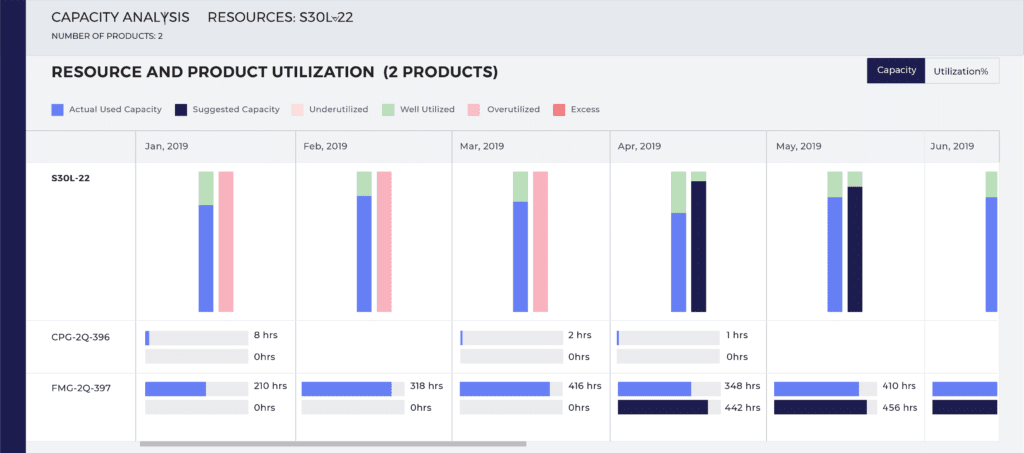

Specific process overview of ThroughPut– month by month suggested utilization and product load:

Key metrics highlighted here:

- Avg machine performance

- Highs and lows including the avg output the machine can produce

- Reliability of lead times and machine times

- Stable processes and unstable processes

- What is the normal performance you can expect based on your current ingredients?

- Do you know where your constraints are?

- Do you know how to meet your demand for certain products?

- Lost sales and opportunities lost due to machine failures

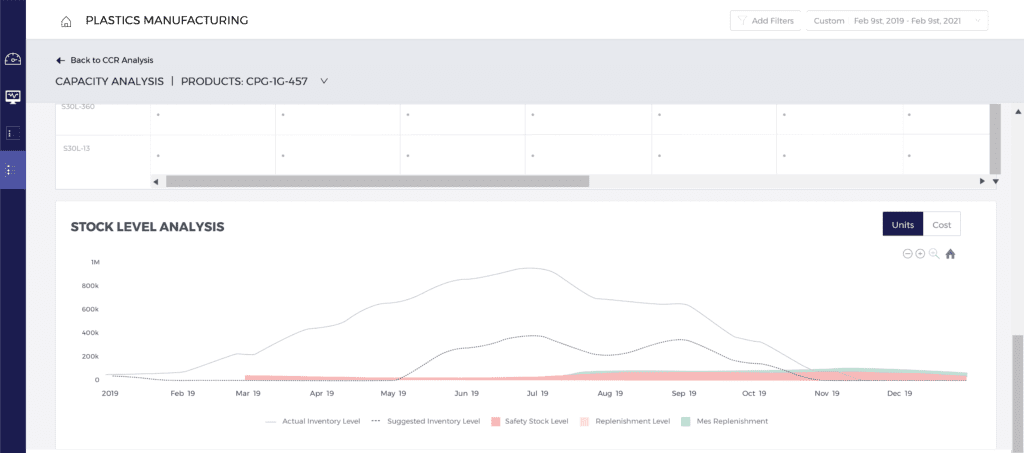

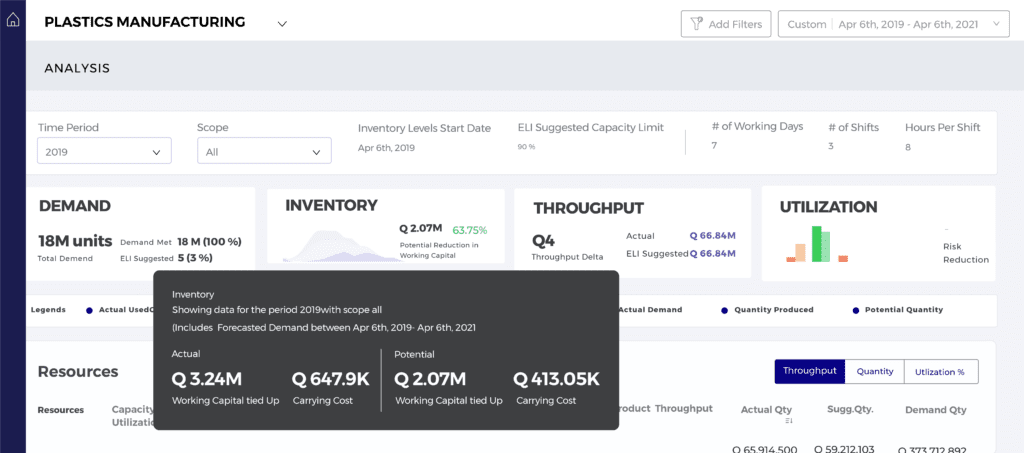

Better Inventory Management

Stay ahead of the game with updated information on inventory levels, irrespective of the market fluctuations impacting your inventory and production.

ThroughPut helps accurately track and trace inventory by providing recommendations on when and where reallocation is possible, usage and demand balance, deep insights on the mid-term and near-term range, and how to distribute and allocate the product to negotiate well with suppliers.

It also gives the next priority based action recommendation, matches inventory availability, and demand dynamics with working capital tied up.

Effective Product Allocation

ThroughPut helps simultaneously pick the best machines for each product while keeping the load on each machine to the accurate levels that can offset any output issues caused by the impact of variation.

Higher Throughput with Minimum Operations Costs

ThroughPut helps control throughput losses by maximizing the real-time demand, keeping the resource utilization under the set capacity limit. This can drastically minimize operations expenses that tap into the purchase of extra capacity.

Superior Service Levels

With ThroughPut, you can easily harness the power of AI-driven capacity planning to ensure you exceed your service expectations and increase profitability.

To learn more about ThroughPut Capacity Planning Solution, schedule a demo here.