Towards AI-driven Congestion-Free Ports and Terminals

Unclogging Maritime Supply Chain Operations by Eliminating Delays and Bottlenecks

The pandemic has been both cruel and kind to the ports industry. When upstream supply chain port operations were disrupted during the early phase of the pandemic, in a bid to remain operationally profitable, over 630 ships were sent for demolition in 2020.

And when markets began opening after the lockdown, the peak in demand was hit by a lack of available vessels and containers, causing a chain reaction impacting the entire supply chain.

Existing vessels are now being utilized to their fullest capacity and deployed on newer optimized routes.

In 2021, with 10% of container capacity grounded, vessel wait times at the Port of Los Angeles peaked at approximately 17 days.

By early 2024, significant improvements were achieved, reducing average waiting times for container ships to about 2.5 days.

As of December 2024, the Port of Los Angeles reported an average time at berth of 5.0 days, indicating continued efficiency in port operations.

The shipping industry contributes to 25% of America’s total GDP with the Port of Los Angeles and Port of Long Beach being the busiest, handling more than 40% of all inbound cargo shipped to the U.S.

Undoubtedly, operational efficiency still tops the ports and terminal priority scorecard, as even minor delays can create a ripple effect disrupting the entire supply chain from shore to shipment.

The pandemic has further weighed down the performance of ports worldwide, with minimal workforce available at terminal hubs and fewer shipping containers on the move, thus bringing global port operations to an abrupt halt.

The Impact of Unprecedented Disruptions on Global Port Supply Chains

Since the onset of the pandemic, maritime trade has been immensely affected. Incidents like the Suez Canal blockage have only worsened the situation with unprecedented delays, rerouting vessels, and shortage of essential equipment and vessel capacity across shipping lines.

Also, a sudden spike of demand for consumer goods and supply chain disruptions have left global supply chain networks strained for longer durations.

Port congestions are the cornerstone of this global crisis and can worsen capacity constraints across global marine lines.

What Causes a Congested Port?

A port congestion occurs when ships arrive at a port but are unable to load or unload due to an existing full port capacity.

Due to this, ships and container vessels have an option to either queue up and wait indefinitely to get a spot which is right for them or report at the nearby accessible port, which again requires additional time and resource commitment.

When the wait turns into days or weeks, this can cost shipping operators a hefty sum, disrupting the entire supply chain.

Some of the associated challenges here include:

- Chaotic overcrowded ports

Port congestions are the new reality that ports across the globe are witnessing and one of the several crises that have gripped the industry in the recent past. With 77% of major global ports staring down snarling backlogs, there is an urgent need to prevent unstable and tense supply chains from toppling into any further chaos. - High operational costs + low efficiency

Along with congestion, high operational costs and low efficiency rates are plaguing the industry further. Fleet and service planners who need to keep costs down work with variable freight rates that rise and fall based on market rates, making it difficult to predict long-term costs. Also, bunkers that account for a large share of total costs need to be managed efficiently to keep costs down and maximize profits. - Manual vessel and service scheduling

Complicated patterns of manual vessel and service scheduling further compound the problem. The tremendous task of scheduling vessels optimally using manual or outdated systems, while still trying to keep costs down is not only redundant but also adds to operational inefficiencies. - Erratic demand and freight rate fluctuations

Schedule reliability is impacted by market demand-supply fluctuations, which often result in liner companies experiencing blank sailing and idling of ships. Port operators therefore need to plan how they will meet supply with demand and match cargo schedules on a real-time basis. - Lags in port terminal operations

Additional pressure on port terminals to cater to a high volume of customers and container consignments requires seamless operational efficiencies to work within the agreed turnaround times. Port terminals have a business.

These changes may cause peaks in volume or lengthen the container delays, which finally impact the terminals’ ability to plan and execute the plan.

Tackling the Domino Effect on Other Supply Chain Components – the Need for Supply Chain Visibility

Port efficiency impacts several stakeholders across the supply chain, including suppliers, port operators, manufacturers, logistics partners and cargo shipping lines.

Without adequate visibility and accurate insights into real-time operational data, none of them are able to work efficiently. All of them need better visibility and insight into how ports work and how bottlenecks can be avoided completely.

The lack of supply chain visibility can paralyze operations right from the port’s docking station to the plant floor where materials are churned out.

With traffic hitting thousands of containers per month, supply chain managers struggle to pinpoint the precise location of their containers in the port pipeline. They also are unaware of when they will be unloaded for distribution.

This in turn makes it challenging to accurately estimate lead times, and schedule onward manufacturing and distribution. Without adopting a holistic approach based on real time end-to-end visibility into port and container operations, it is impossible to plan subsequent business operations effectively.

Navigating Maritime Supply Chain Visibility with AI

Port congestion is a symptom of underlying supply chain issues, amplified by limited visibility that can create a sweeping impact on port operations.

Having a reliable demand-driven approach to ports and terminal visibility is key to a port operator’s ability to meet uncertain demands, especially in the current market scenario.

While shippers struggle with container delays, transit time variances, and the additional burdens of detention and demurrage, having comprehensive AI-driven end-to-end visibility capabilities can reduce supply chain risks.

By deploying an AI-enabled data-driven approach to demand planning and segmentation, port operators can overcome the challenges thrown by an increasingly volatile supply chain.

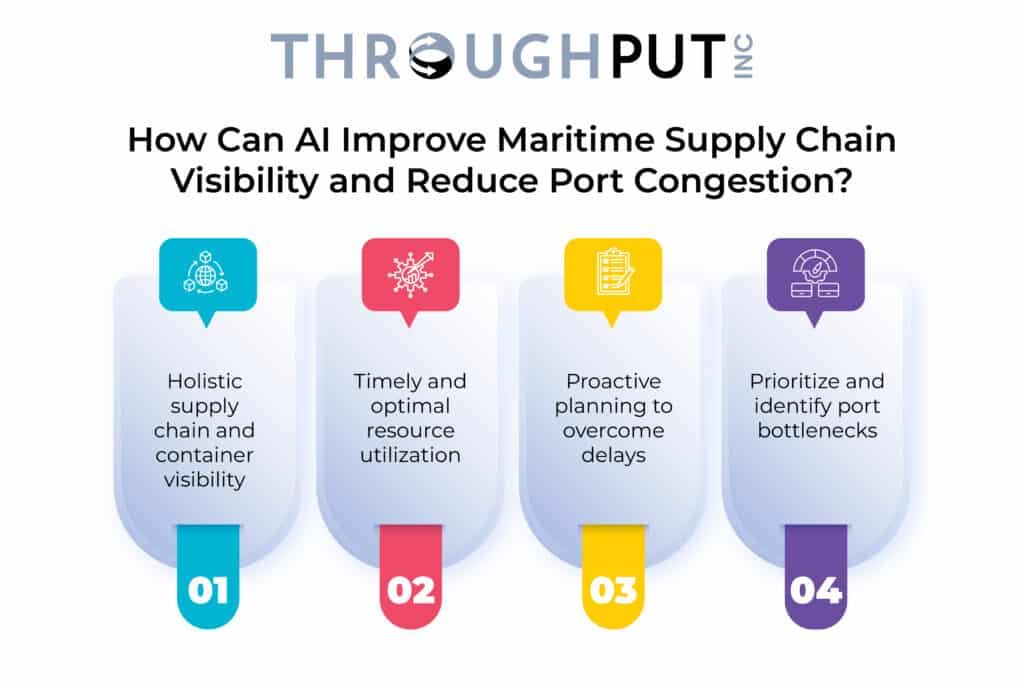

By moving away from manual outdated legacy systems, real-time insights can help them achieve the much needed efficiencies to identify and eliminate bottlenecks at the right time and avoid an over clogged supply cycle. Some of the benefits include:

1. Holistic supply chain and container visibility

Shipping ports need to line up containers which should be taken off the shift first, in sync with the priority of perishable products and non-perishable goods. AI helps prioritize these containers with deep insights to avoid loss and wastage and thus intelligently handle container allocation.

2. Timely and optimal resource utilization

AI-driven inputs can help remove communication gaps to allow transport carriers with quicker scheduling to carry containers in the ports. With optimal route plans in place, port operators are able to enjoy better resource utilization based on available capacity and reduce bottlenecks in chassis allocation.

3. Proactive planning to overcome delays

With unforeseen surprises thrown across shipping schedules causing delivery disruptions, AI can provide valuable predictive analysis using data-driven intelligent recommendations to help make proactive decisions and adapt operations on the fly.

4. Prioritize and identify port bottlenecks

The key to unclogging congested ports is to get end-to-end visibility of the flow of goods through high-volume terminal points across each tier of the supply chain. AI helps rank port vulnerabilities to analyze severity concerning a particular SKU.

Breakthrough the Clutter and Boost Ports & Terminal Efficiency with ThroughPut AI

ThroughPut’s AI-powered solution provides better visibility of vessels and shipments, to help operators mitigate risks caused by external disruptions and plan ahead to reroute shipments.

Timely data-focused insights can help them make adequate transport arrangements from ports and to efficiently balance cost and delivery times.

ThroughPut helps connect procurement and logistics to a real-time knowledge graph of supply chains, to enable businesses identify potential bottlenecks sooner rather than later, allowing them to avert losses and missed deliveries, and eventually maximize share of wallet as well as profit margins.