Understanding Supply Chain Management KPIs to Fuel a Company’s Financial Performance

By now, everyone seems to understand that supply chain has the potential to transform into a key competitive advantage for businesses.

It is an open secret that supply chain and finance are inextricably linked and that supply chain efficiency can have a direct impact on the company’s revenue.

However, ‘how to align the two functions in a way that the impact of supply chain improvements on financial performance can be tracked, controlled and demonstrated’ is a question that most supply chain leaders are grappling with.

In this blog, we’ll introduce you to the supply chain management KPIs that influence the company’s bottom line, and how you can track and measure it effectively.

Supply Chain Management and Finance are Closely Connected

Even though supply chain management takes up a significant share of a company’s budget, finance and supply chain management have mostly worked on parallel tracks without much convergence.

Cost optimization and risk management in supply chain management is of particular interest to finance. In the post-pandemic world, the ability to manage these supply chain costs while boosting revenue is also emerging as a key area of interest for CFOs.

For instance:

- How much working capital can be freed up with 5% reduction in inventory?

- How much can the Cost of Goods Sold be enhanced by improving materials’ usage?

- How much more revenue can be generated with accurate demand forecasting?

Strategic supply chain management with a focus on financial flow along with material and information flow is critical to the success of any business.

But what are the Key Performance Indicators (KPI) in supply chain management that you need to look at from a financial lens?

Supply Chain Management KPIs that Demonstrate Impact on Financial Performance

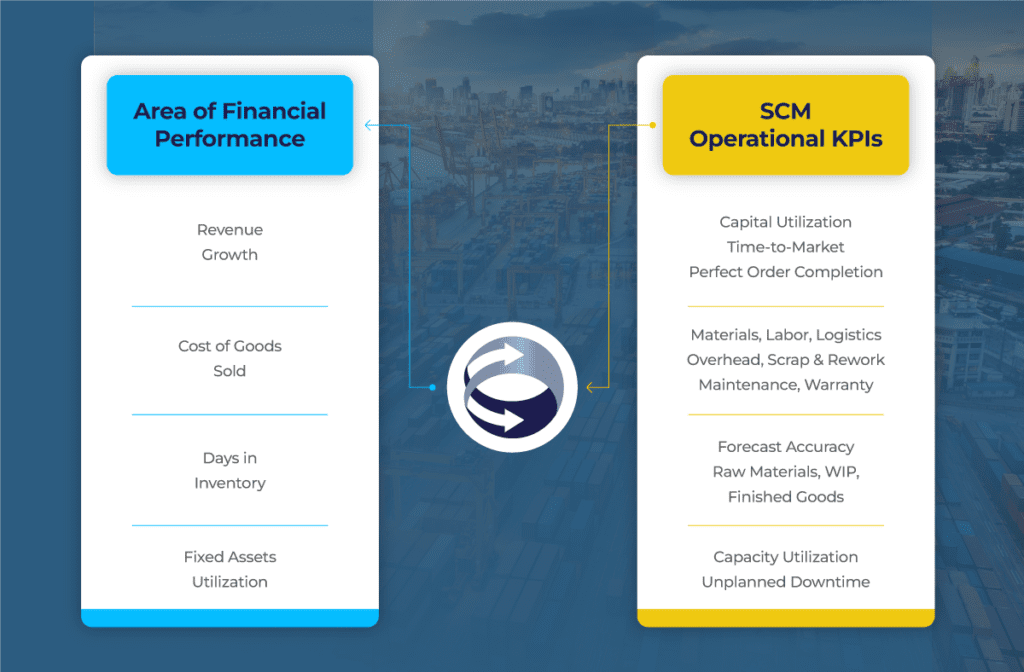

As the above image outlines, finance is particularly interested in all the metrics on the left hand side including revenue growth, cost of goods sold, days in inventory and fixed assets utilization. These directly affect business performance.

What you can’t miss out are the supply chain metrics outlined on the right hand side which influence these finance metrics. Here’s how.

- Capital Utilization

Capital utilization refers to the efficient allocation and utilization of financial resources, including assets, investments, and capital equipment, within a company and in this case, the supply chain.

Effective capital utilization in the supply chain can maximize return on investment, optimize cost and can free up cash for product development and further investment.

- Time-to-Market

Time-to-market refers to the time it takes for a company to develop and launch a product or service into the market. Faster time-to-market enables companies to generate revenue sooner, capture more market share with the first-mover advantage and avoid additional expenses associated with extended development cycles, such as higher research and development costs, additional marketing expenses, or potential revenue losses due to delayed market entry.

- Perfect Order Completion

Perfect order completion refers to the ability to fulfill customer orders accurately, on time, and in full. Its financial implications include enhanced customer satisfaction and thereby, repeat purchases and more sales through word of mouth.

- Material Usage

The effective usage, production and storage of raw materials has a significant impact on a company’s financial performance. By optimizing material consumption, reducing waste, and minimizing scrap or rework, companies can lower their raw material expenses.

This leads to improved cost control and increased profitability. Similarly, minimizing overstocking can improve cash flow and also free up working capital for the production of more “high-demand” products.

- Capacity Utilization and Unplanned Downtime

Using your capacity to its optimum and pre-empting downtime to avoid unplanned disruptions are two key areas that not only affect supply chain operations but also your business’ overall financial health.

Proper handling, measurement, and control of materials during production processes can lead to increased throughput, reduced downtime, and improved overall equipment effectiveness (OEE).

Managing these key supply chain management metrics can enable you to have a positive impact on the company’s financial performance. However, to demonstrate the impact to the C-suite, supply chain leaders must be able to visualize and report on the supply chain- finance correlation.

Here’s where ThroughPut comes into the scene.

ThroughPut for Supply Chain Management through a Financial Lens

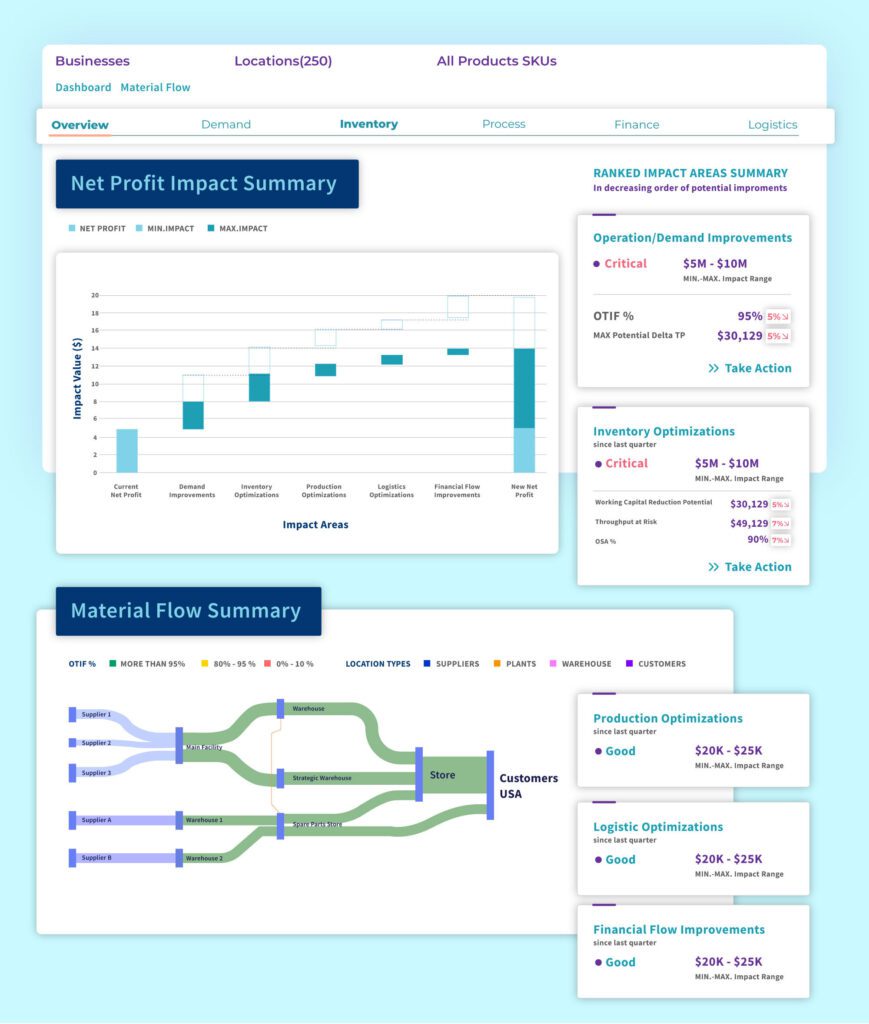

ThroughPut is built for supply chain leaders who want to position supply chains as a profit center. One of the primary views on ThroughPut’s software is contributions of each area of impact on the net profit metric to assimilate all the interrelationships and dependencies that are an inherent part of the modern supply chain.

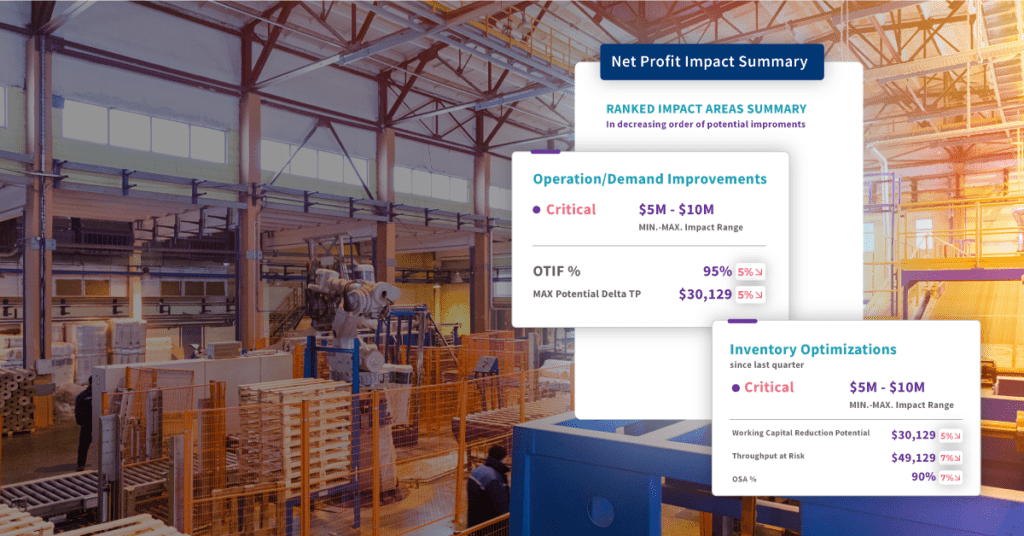

ThroughPut’s ‘Net Profit Impact Summary’ view summarizes the minimum and maximum range of impact across all functional areas and shows the overall expected Net Profit impact at the Company or Business Unit level after addressing all evaluated impact areas.

ThroughPut’s cash flow conversion cycle analysis and a powerful overview of accounts payable, accounts receivable, and inventory turns enables businesses to:

- Quickly highlight high-impact areas that can improve free cash flows

- Leverage actionable recommendations to accelerate financial gains quickly

- Analyze recent change indicators to display the trajectory of business growth and how to best realize identified and predicted financial benefits

To delve deeper into the capabilities of ThroughPut, talk to our team.

Watch the full webinar on the supply chain-finance connection with Dr. Stephen Timme, the Founder and President of FinListics Solutions and Steve Robinson, CEO of the Supply Chain Project joined by Ali Raza, Founder and CEO of ThroughPut.