What is Vendor Managed Inventory (VMI)? Supply Chain Explained.

Vendor managed inventory (VMI) is a collaborative supply chain management strategy where the vendor (supplier) manages the inventory levels at the customer’s location. This management involves the vendor monitoring stock levels, forecasting demand, and replenishing inventory.

How does VMI work?

VMI works through leveraging a couple of important elements:

Information Sharing

The customer shares relevant data with the vendor, such as sales data, inventory levels, and forecasts, through electronic data interchange (EDI) or other automated systems.

Inventory Monitoring

The vendor uses this data to monitor the customer’s real-time inventory levels. They can track sales trends, identify potential stockouts, and adjust replenishment orders accordingly.

Replenishment

The vendor is responsible for replenishing the customer’s inventory, ensuring that there is always enough product to meet demand. They may use various methods for demand driven replenishment, such as regular deliveries, just-in-time (JIT) deliveries, or consignment inventory.

Performance Measurement

The vendor and customer agree on performance metrics, such as inventory turnover, service levels, and cost savings. They regularly review these metrics to evaluate the VMI program’s success and identify areas for improvement.

What is the purpose of VMI?

The primary purpose of Vendor Managed Inventory (VMI) is to optimize inventory levels and improve supply chain efficiency for both the vendor (supplier) and the customer (retailer or distributor). This is achieved by transferring the inventory management responsibility from the customer to the vendor, who has better visibility into demand patterns and production capabilities.

The specific goals of VMI include:

- Reducing Inventory Costs: Vendors can optimize inventory levels by leveraging their expertise and data analysis, reducing the risk of overstocking or stockouts. This action leads to lower inventory holding costs for the vendor and the customer.

- Improving Service Levels: VMI ensures that the right products are available at the right time, minimizing the risk of lost sales due to stockouts. This results in improved customer satisfaction and strengthens the vendor-customer relationship.

- Increasing Sales: With optimal inventory levels, customers can more effectively meet demand, leading to increased sales and revenue.

- Streamlining Supply Chain Operations: VMI automates and optimizes inventory management tasks, freeing up vendor and customer resources to focus on other strategic priorities.

- Strengthening Supplier Relationships: VMI fosters closer collaboration and trust between vendors and customers as they work together to achieve mutual goals.

In short – VMI is a strategic approach to inventory management that aims to create a win-win situation for both suppliers and customers by improving efficiency, reducing costs, and enhancing service levels.

What is the main benefit of VMI for retailers?

The main benefit of VMI for retailers is a reduction in inventory costs. By transferring the responsibility of inventory management to the vendor, retailers reduce the amount of capital tied up in inventory and the costs associated with storing and managing it. This can free up resources for other investments and improve the retailer’s overall financial performance.

Additionally, VMI can lead to:

- Improved service levels: Vendors are incentivized to maintain optimal inventory levels to avoid stockouts, ensuring that retailers have the products customers want when they want them.

- Increased sales: By having the right products in stock at the right time, retailers can increase sales and improve customer satisfaction.

- Stronger supplier relationships: VMI fosters closer collaboration and trust between vendors and retailers.

While the primary benefit for retailers is cost reduction, the other advantages contribute to a more efficient and profitable operation.

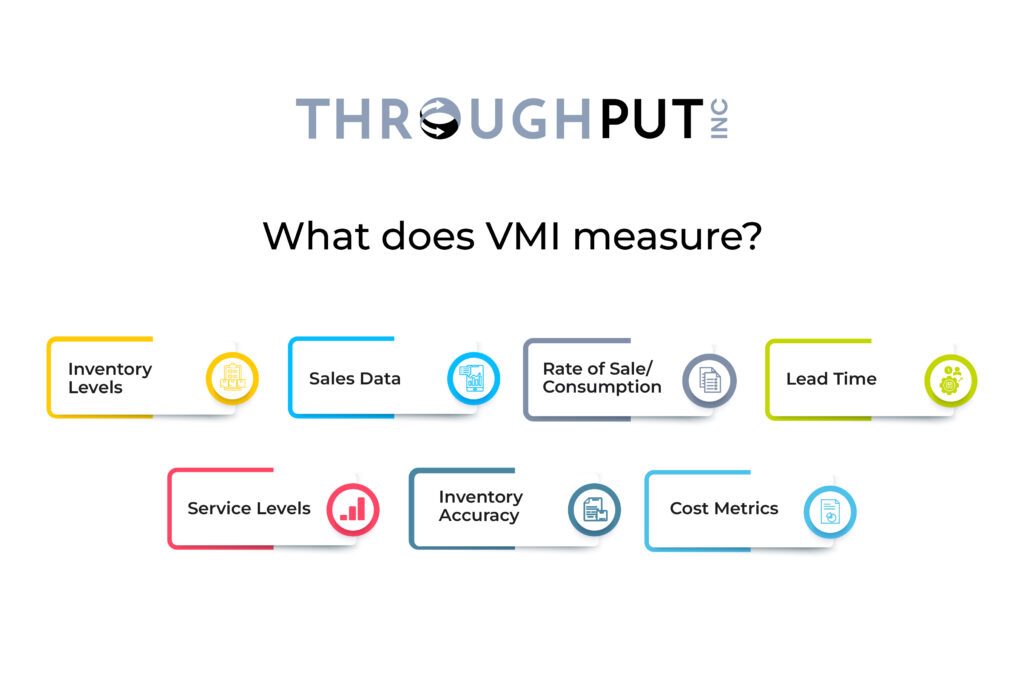

What does VMI measure?

Vendor Managed Inventory (VMI) primarily measures inventory-related metrics to ensure optimal inventory levels and efficient replenishment. These metrics can include a variety of data points.

Inventory Levels

The actual quantity of inventory on hand at the customer’s location is tracked in real-time or near real-time. The vendor ensures that inventory is sufficient to meet demand without overstocking.

Sales Data

VMI systems track sales data to understand demand patterns, identify trends, and forecast future demand. This information is crucial for the vendor to make informed decisions about replenishment quantities and timing.

Rate of Sale/Consumption

This metric measures how quickly products are sold or consumed at the customer’s location. It helps the vendor determine the appropriate replenishment frequency and avoid stockouts.

Lead Time

The time it takes for the vendor to replenish inventory after receiving an order is a critical factor in VMI. By monitoring lead times, vendors can ensure timely replenishment and avoid disruptions in the supply chain.

Service Levels

VMI often includes service level agreements (SLAs) that define the expected level of product availability and on-time delivery. These metrics are tracked to ensure that the vendor meets customer service expectations.

Inventory Accuracy

Maintaining accurate inventory records is essential for effective VMI. Regular inventory audits and cycle counts ensure that the physical inventory matches the records in the VMI system.

Cost Metrics

VMI systems may track various cost metrics, such as inventory holding costs, ordering costs, transportation costs, and overall inventory management costs. These metrics help evaluate the VMI program’s cost-effectiveness and identify areas for improvement.

In addition to these core inventory metrics, VMI may track other relevant data, such as promotional activities, seasonality, and external factors influencing demand.

VMI KPIs Dashboard (Conceptual Overview)

A VMI KPIs dashboard acts as the control tower for vendor-managed inventory, translating raw inventory and consumption data into actionable insights for business leaders. Instead of relying on periodic reports or manual reviews, the dashboard provides real-time, decision-ready visibility into how inventory is performing across locations, suppliers, and SKUs.

At its core, the dashboard answers four critical executive questions:

1. Is our inventory healthy or at risk?

The dashboard aggregates on-hand inventory, consumption velocity, safety stock, and forecast signals into an inventory health view. Leaders can instantly see which SKUs are overstocked, which are approaching shortage, and which are optimally balanced. This prevents excess working capital lock-up while reducing the risk of production or sales disruptions.

2. Where are stockouts likely to occur—and why?

Stockout risk indicators use historical consumption trends, lead-time variability, and upcoming demand signals to highlight future shortages before they happen. This shifts VMI from reactive replenishment to proactive risk prevention, enabling suppliers to adjust replenishment plans early rather than relying on emergency orders.

3. Are suppliers meeting their commitments?

Supplier performance metrics such as fill rate, on-time replenishment, lead-time adherence, and service-level compliance are continuously tracked. This creates clear accountability for vendors managing inventory and allows procurement teams to identify underperforming suppliers, renegotiate SLAs, or rebalance sourcing strategies.

4. What is the financial impact of VMI?

The dashboard connects inventory decisions directly to financial outcomes by showing capital tied up in inventory, inventory turns, carrying cost trends, and emergency procurement frequency. Leaders can clearly see how VMI is impacting working capital, freight spend, and overall operating cost—making ROI measurable and defensible.

Additionally, tracking emergency PO and expedited shipment trends helps organizations identify structural issues in replenishment logic, demand forecasting, or supplier reliability. A declining trend indicates a mature, well-tuned VMI program, while spikes signal areas requiring intervention.

In summary, a VMI KPIs dashboard transforms VMI from a supplier-driven operational process into a strategic, performance-managed program. It enables faster decisions, tighter supplier governance, lower inventory costs, and higher service levels—making it a critical capability for organizations evaluating modern, technology-enabled VMI solutions.

When should VMI be used?

VMI should be used when:

- The company wants to reduce inventory costs. VMI allows the vendor to manage inventory levels, which can reduce the customer’s inventory holding costs.

- The company wants to improve service levels: VMI can help prevent stockouts and ensure customers always have the necessary products.

- The company wants to increase sales: By having the right products in stock at the right time, VMI can help to increase sales and improve customer satisfaction.

- The company wants to build stronger supplier relationships: VMI can foster closer collaboration and trust between suppliers and customers.

- The company has a complex supply chain or limited resources for inventory management: VMI can be a good option for companies that lack the expertise or resources to manage their own inventory effectively.

- Demand is relatively stable and predictable: This would allow the vendor to forecast demand and replenish inventory accordingly and accurately.

- The vendor has expertise in inventory management, which can help optimize inventory levels and improve supply chain performance.

- The customer and vendor have a good working relationship: Trust and communication are essential for successful VMI implementation.

It’s important to note that VMI is not a one-size-fits-all solution and may not be appropriate for all situations. The decision to implement VMI should be based on a careful analysis of the customer and vendor’s specific needs and circumstances.

Who benefits from vendor managed inventory?

Both vendors and customers benefit from VMI.

Here is how vendors benefit from VMI:

- Increased Sales and Customer Loyalty: VMI allows vendors to have better visibility into their customers’ inventory levels and consumption patterns, enabling them to replenish stock and prevent stockouts proactively. Customers are more likely to continue purchasing from a supplier who consistently meets their needs.

- Improved Forecasting and Planning: Vendors can improve their demand forecasting and production planning by having access to real-time data on customer demand and inventory levels – which means optimized inventory management and reduced costs.

- Stronger Customer Relationships: VMI supports closer collaboration and trust between vendors and customers as they work together to optimize inventory levels and improve supply chain efficiency.

- Competitive Advantage: Vendors who offer VMI can differentiate themselves from competitors and gain a competitive advantage.

Here is how Customers (Retailers or Distributors) benefit from VMI:

- Reduced Inventory Costs: By transferring the inventory management responsibility to the vendor, customers can reduce their inventory holding costs, freeing up capital for other investments.

- Improved Service Levels: VMI helps to prevent stockouts and ensure that customers always have the products they need

- Reduced Administrative Burden: VMI eliminates the need for customers to manually track inventory levels and place replenishment orders, freeing up staff to focus on other tasks.

- Access to Supplier Expertise: Vendors often have specialized knowledge and expertise in inventory management, which they can leverage to optimize inventory levels and improve customer supply chain performance.

What is the difference between VMI and traditional inventory management?

The main difference between VMI and traditional inventory management lies in who is responsible for managing inventory levels and making replenishment decisions.

In traditional inventory management, the retailer or customer manages their inventory. They track inventory levels, forecast demand, and place orders with the supplier when inventory reaches a certain reorder point. This approach can be time-consuming and, if not managed carefully, may lead to inaccurate forecasts and stockouts.

Vendor managed inventory (VMI) means that the vendor or supplier manages the customer’s inventory. They can access the customer’s inventory data to monitor stock levels, forecast demand, and automatically replenish inventory as needed. This approach can lead to more accurate forecasts, reduced inventory costs, and improved service levels, as the vendor is incentivized to keep the customer’s shelves stocked.

VMI shifts the burden of inventory management from the customer to the vendor, leveraging the vendor’s expertise and data-driven insights to optimize inventory levels and improve supply chain efficiency for both parties.

What is the disadvantage of VMI?

The main disadvantage of VMI is the high level of trust and collaboration required between the vendor and the customer. Sharing sensitive information such as sales data, inventory levels, and forecasts can be a concern for some companies, as it requires a high degree of transparency and may raise confidentiality issues.

Additionally, VMI requires investment in technology, such as EDI systems and inventory management software, which can be costly for smaller businesses.

Finally, implementing VMI may necessitate significant changes to existing business processes, potentially leading to resistance from employees accustomed to traditional inventory management methods.

What are some examples of VMI?

A well known example of VMI is the relationship between Walmart and Procter & Gamble. In this arrangement, Procter & Gamble manages Walmart’s diaper inventory, monitoring stock levels and automatically replenishing them as needed.

This allows Walmart to reduce its inventory holding costs and avoid stockouts, while Procter & Gamble gains better visibility into demand patterns and can plan its production accordingly. P&G monitors Walmart’s inventory levels, forecasts demand, and automatically replenishes stock as needed.

This arrangement benefits both companies. Walmart benefits from reduced inventory holding costs and the assurance that its shelves are always stocked with P&G products. P&G benefits from having better visibility into demand patterns, which allows it to optimize its production and distribution.

Additional Examples of VMI

- Campbell Soup Company and Kroger: Campbell Soup Company manages the inventory of its soups at Kroger grocery stores.

- PepsiCo and 7-Eleven: PepsiCo manages the inventory of its beverages at 7-Eleven convenience stores.

- Black & Decker and Home Depot: Black & Decker manages the inventory of its tools at Home Depot stores.

These examples demonstrate how VMI can be applied across various industries and product categories, highlighting its versatility as a supply chain management strategy.

Final words on VMI

Vendor Managed Inventory (VMI) is a collaborative strategy where suppliers take charge of managing inventory levels at a customer’s location. VMI aims to optimize inventory levels, reduce costs, and improve service for both parties.

Retailers benefit from reduced holding costs, improved service levels, increased sales, and stronger supplier relationships. Suppliers gain better demand visibility, improved forecasting, and increased customer loyalty.

VMI is particularly useful when inventory management is complex, demand is predictable, the vendor has expertise, and a good working relationship exists.

FAQs for Vendor Managed Inventory (VMI)

Question 1. How can VMI help reduce unplanned downtime for maintenance-intensive industries?

Answer:

VMI ensures that critical spare parts and consumables are always available at the right location by giving suppliers real-time visibility into stock levels, consumption patterns, and upcoming maintenance schedules. For heavy industries, this minimizes stockouts that cause line shutdowns and production losses. Advanced VMI with AI/ML can predict part failures, recommend reorder triggers, and automate replenishment—directly supporting maintenance reliability and uptime goals.

Question 2. What measurable ROI can executives expect after implementing VMI in supply chain and procurement operations?

Answer:

Most industrial companies achieve:

- 15–40% reduction in inventory carrying costs

- 20–35% lower stockouts

- 10–25% improvement in supplier service levels

- 5–12% lower procurement administrative cost

- Improved working capital utilization due to better demand visibility

Additionally, AI-driven VMI systems improve reorder accuracy, reducing excess and obsolete inventory while ensuring consistent material availability for operations.

Question 3. How does VMI support strategic sourcing teams in building supplier accountability and transparency?

Answer:

VMI requires suppliers to take responsibility for monitoring inventory levels and maintaining agreed-upon service KPIs. With digital VMI systems, sourcing teams get real-time dashboards showing supplier fill rates, on-time replenishment, lead time variance, and cost-to-serve. This transparency strengthens supplier contracts, drives performance-based agreements, and reduces manual supplier follow-ups.

Question 4. How does AI-enhanced VMI improve forecast accuracy for slow-moving or unpredictable industrial SKUs?

Answer:

AI models analyze machine usage patterns, seasonality, maintenance logs, BOM-level consumption, and historical procurement trends to generate probabilistic forecasts even for intermittent demand. This leads to more accurate reorder points, optimized safety stock, and smarter replenishment policies—significantly outperforming traditional min-max or rule-based VMI.

Question 5. What risks come with VMI, and how can leaders mitigate them?

Answer:

Key risks include over-reliance on suppliers, data integration complexity, and potential excess inventory if parameters are misconfigured. Mitigation strategies:

- Define clear KPIs (fill rate, stock turns, lead time adherence)

- Maintain approval workflows for high-value SKUs

- Use AI-based parameter tuning to avoid overstocking

- Establish shared inventory visibility across procurement, operations, and suppliers

This ensures balanced control and performance across all parties.

Question 6. How does VMI improve CAPEX and OPEX planning for industrial operations?

Answer:

By reducing emergency purchases, avoiding premium freight, and lowering working capital locked in inventory, VMI improves OPEX efficiency. Demand-driven replenishment also helps forecast future CAPEX needs based on equipment usage and lifecycle patterns. Leaders gain a predictable view of spend, enabling smarter budget allocation across maintenance, production, and supply chain.

Question 7. Can VMI integrate with our existing ERP, MRO, CMMS, or MES systems?

Answer:

Yes. Modern VMI solutions integrate with SAP, Oracle, MS Dynamics, Infor, Maximo, and other industrial ERPs/CMMS tools. AI-driven VMI platforms can operate even with incomplete data by cleaning, categorizing, and modeling consumption patterns. Real-time integration provides accurate stock levels, usage trends, and automated PO or replenishment triggers.

Question 8. How does VMI help reduce procurement workload and manual PO creation?

Answer:

In VMI, suppliers manage inventory levels directly, reducing the requirement for buyers to monitor stock, raise POs, chase suppliers, or manage min/max exceptions. Automated replenishment lowers administrative load and lets procurement focus on strategic tasks like cost negotiation, supplier diversification, and contract optimization.

Question 9. Which types of SKUs are ideal for VMI in industrial operations?

Answer:

VMI delivers maximum value for:

- Fast-moving MRO parts

- Critical spare parts with high downtime impact

- Consumables (lubricants, chemicals, adhesives, fasteners, filters)

- Predictable repetitive components

AI-powered VMI can also manage slow-moving or intermittent items by predicting usage patterns based on maintenance logs, sensor data, and historical consumption.

Question 10. How does AI-powered VMI help reduce emergency procurement and expedited logistics costs?

Answer:

AI models identify early consumption spikes, maintenance-triggered demand, and lead-time deviations—flagging risks before they become stockouts. The system automatically accelerates or adjusts replenishment orders to prevent emergencies. This reduces costly expedited shipping, last-minute supplier sourcing, and downtime-driven losses.

Question 11. How do we measure the success of a VMI program?

Answer:

Key metrics:

- Stockout rate & impact on production downtime

- Inventory turns and carrying cost reduction

- Supplier fill rate & on-time delivery performance

- Reduction in urgent/emergency orders

- Forecast accuracy improvement

- Working capital savings

These KPIs help executives quantify value and continuously improve supplier performance.

Question 12. How does VMI support sustainability and ESG goals?

Answer:

VMI reduces waste from excess inventory, minimizes emergency freight (lower emissions), and optimizes supplier logistics routes. Additionally, better forecasting prevents overproduction and supports sustainable sourcing by improving supply chain visibility.

Question 13. What is the role of probabilistic forecasting in next-gen VMI systems?

Answer:

Probabilistic forecasting models predict multiple demand outcomes instead of a single deterministic number. This helps optimize safety stock, reduce risk buffers, and improve service levels—especially for critical parts with uncertain demand patterns. It allows leaders to plan inventory based on risk tolerance and operational urgency.

Question 14. How can VMI be used in multi-plant or multi-warehouse networks?

Answer:

AI-driven VMI dynamically allocates stock across facilities based on real-time consumption, production schedules, and inventory health scores. It prevents overstock at one plant while another faces shortages, ensuring optimal network inventory and reducing overall working capital.

Question 15. What transformation steps are required to move from traditional min/max to AI-driven VMI?

Answer:

Steps include:

- Data extraction & cleansing (ERP/MRO/CMMS)

- SKU segmentation based on criticality & usage patterns

- Identification of optimal reorder triggers

- AI model training & back-testing

- Supplier onboarding & KPI definition

- Automated replenishment pilot

- Scale to network operations

This structured approach ensures rapid time-to-value.