Top 5 Use Cases of New-age Demand Planning and Forecasting Solutions

The supply chain world can now be easily categorized into phases – Pre-covid and Post-covid. A lot of things have changed in the post-covid phase which has significantly impacted the way things work and the results they produce.

Chief Supply Chain Officers (CSCOs) today have to deal with a new set of challenges including supplier unpredictability, ambiguous and missing historical data, inventory disruptions, supply and demand imbalances, to name a few.

Supply chain planners need to constantly ensure inventory levels are optimized round the clock to meet erratic customer demand, while also outperforming competition. To add to these existing woes, CSCOs need to ensure accurate decisions while reacting to market changes almost immediately.

Reinforcing this is a finding from Gartner which states that 60% of CSCOs are expected to make faster, more accurate and consistent decisions, and most often in real-time.

The key questions here for CSCOs are:

- How can they make accurate real-time decisions?

- How can demand planning match the pace of market dynamics?

- How can AI-powered tools and solutions enable success in this new reality?

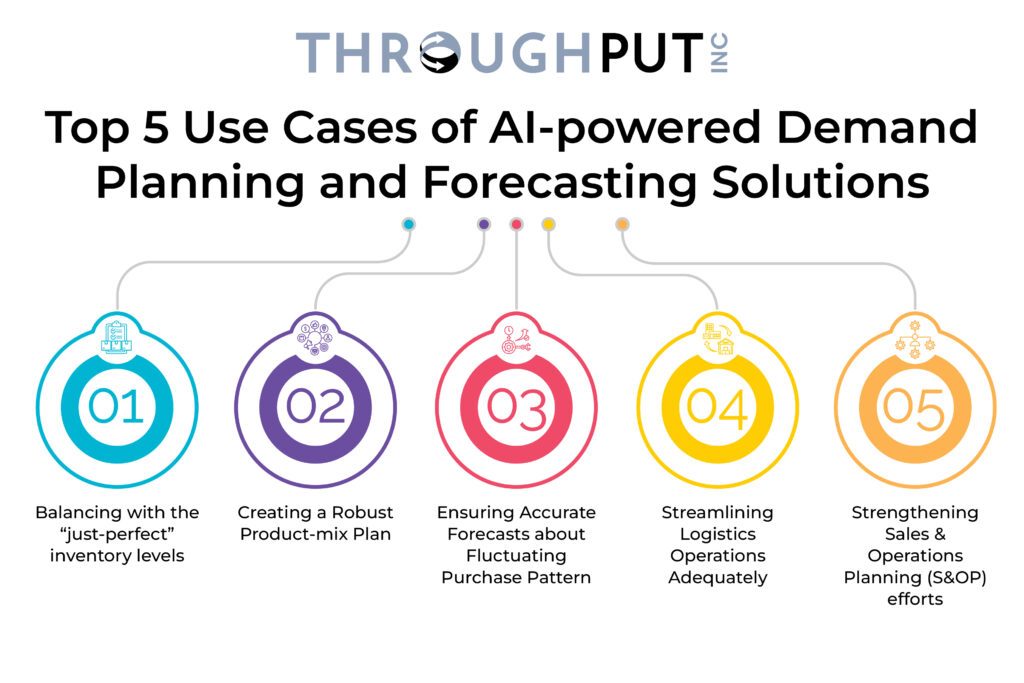

The Top 5 Use Cases of AI-powered Demand Planning and Forecasting Solutions

1. Balancing with the “just-perfect” inventory levels

The right amount of inventory levels can create the ideal synchronized supply chain, however, the trick here is to order just the right amount of each product. This ensures customer demands are met without creating scenarios of overstocking or stockouts.

AI-driven demand planning ensures a consistent balance between demand and supply by adequately avoiding all possible constraints and bottlenecks.

Available data sources are analyzed in real-time which helps optimize inventory levels continuously and as a result, supply chain planners have the most profitable purchasing plan readily available to be implemented at any point in time.

2. Creating a Robust Product-mix Plan

A diversified product-mix creates both a robust brand identity as well as market domination. The length and girth of a company’s product mix can amplify its authority as a market force as well as add to its bottom line.

An AI-powered demand planning and forecasting solution can contribute towards designing the right product-mix strategy as it provides real-time feeds complemented by AI-based analysis.

This helps product marketers and AI-oriented supply chain planning professionals analyze market gaps and peak purchase periods, to decide when to roll out new products, which products to produce in what quantity and which ones to pull out of the market. It also provides the much needed product visibility and viability.

3. Ensuring Accurate Forecasts about Fluctuating Purchase Pattern

Demand volatility has a huge, searing impact on the accuracy of demand forecasts as short-term data availability is always a challenge. Getting the right data inputs that correlate with varying customer purchase patterns is becoming increasingly complex, and therefore, that much harder to detect or predict.

Using AI, demand planners can easily move away from traditional predictive analysis using historical data towards real-time predictions and forecasts.Using AI provides the ease to automatically recognize demand patterns, identify complicated demand-supply relationships and flag critical signals for demand fluctuation.

This helps avoid inefficiencies caused by misalignment of demand and supply throughout the supply value chain.

4. Streamlining Logistics Operations Adequately

Logistics plays an important role in producing profitable operational outcomes for any organization. AI-enabled demand planning and forecasting can directly impact logistics efficiencies with concrete real-time action plans to support decision-making based using intelligent data analytics.

When logistics operators rely on AI-powered demand planning and take actions accordingly, these insights can increase accuracy of forecast results. This helps optimize existing replenishment plans to make advanced predictions using internal and external data sources such as demographic data, weather, traffic conditions etc.

This also helps streamline supply chain networks that impact logistics outcomes to plan, execute and prepare the delivery schedules intelligently.

5. Strengthening Sales & Operations Planning (S&OP) efforts

Supply chain managers always have the pressure to adequately fulfill their future orders and ensure the sales and operations plans are in sync with inventory levels. With an AI- driven demand planning solution, supply chain planners can be assured of a strong S&OP which incorporates all possible demand and supply constraints.

The replenishment plans are, therefore, more realistic and aligned with the market conditions and these can be tweaked based on real-time changes.

ThroughPut’s AI-powered Demand Forecasting Software Shows the Way Ahead

According to PwC, AI applications have the power to transform the way business is done and contribute up to $15.7 trillion to the global economy by 2030. Today, AI can seed the much needed agility and precision in supply chain optimization with streamlined demand planning. It can also trigger a transformational increase in operational and supply chain efficiencies and a decrease in costs.

In a world where CSCOs are short on time, with the mounting pressure to slash down operational costs, ThroughPut’s AI-based demand sensing solution can provide actionable insights that eliminate bottlenecks from the demand planning and forecasting process.

This helps unlock real-time value and ensure planners get a headway in accurate decision making.

You might also like:

Demand sensing for your supply chain: Turn insights into action

AI-powered demand sensing: 7 strategies to increase sales

ThroughPut’s demand sensing tool for a resilient supply chain