How to Enhance Supply Chain Efficiency: A Failproof Framework by ThroughPut

An uncertain market continues to upend supply chains. Escalating costs are becoming a growing concern for most companies. No wonder then that most businesses continue to obsess over supply chain efficiency even in 2023, three years after the outbreak of COVID-19.

So much so that the CFOs’ focus on supply chain-related cost reduction nearly doubled in less than six months last year, from 20% to 39%.

Unfortunately, most supply chain finance solutions remain short-term and functionally focused as many executives continue to prioritize short-term cost goals over long-term business value.

With a narrow, function-specific focus toward supply chain efficiency, risk resilience, and cost reduction, many businesses continue to limit their ability to drive adequate change – whether it be in terms of meeting demand or maximizing profitability.

Now more than ever, there is a need for holistic financial supply chain management.

In other words, supply chain finance solutions need to orchestrate business operations end to end, ranging from demand planning and procurement of raw material, through to production, inventory management, and demand fulfillment, and further on to sustainability and waste management.

Get the Supply Chain Efficiency Framework Right

There’s no magic bullet to supply chain efficiency. Even the biggest and best brands are struggling to gain some control over bleeding supply chain costs. There are, of course, a lot of things you could try to do to minimize costs.

But without the right framework, you’ll end up grasping at straws (way too many of them!), only to find yourself circling back to where you began.

Set the Right Foundation

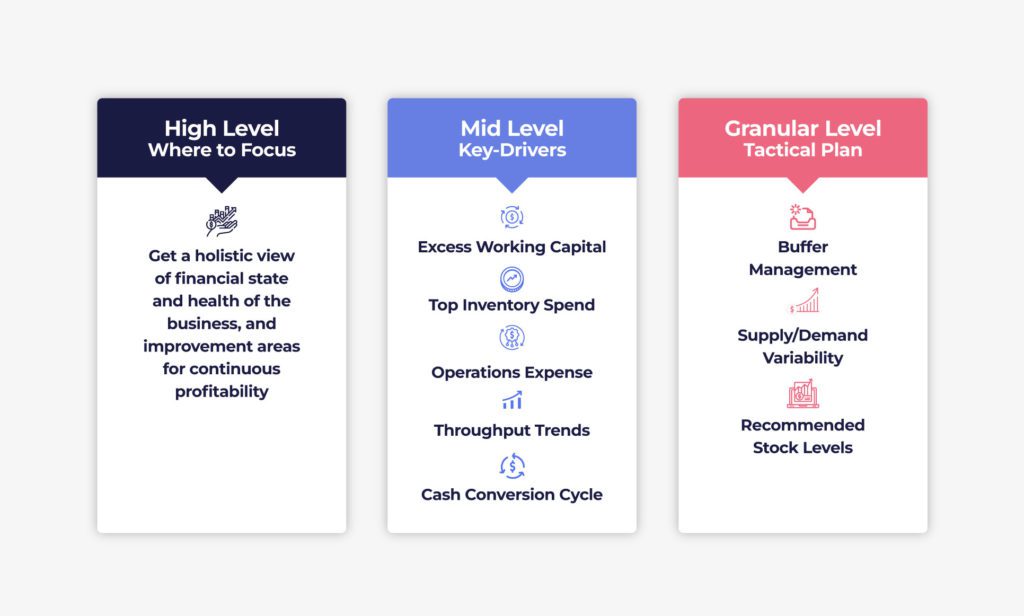

To maximize cost savings and supply chain efficiency, you essentially need to drive operational improvements at three levels:

- High Level

At the high level, you first need to get a holistic, company-wide view of the financial health of the business, and be able to highlight potential improvement areas that can drive continuous profitability. This will help you determine where to focus your efforts, and prioritize them to maximize revenue. - Mid Level

At this level, you should focus on identifying the key drivers of the proposed changes. These could be excess working capital, overrunning inventory spend, operational expense leaks, less-than-optimum throughput, or prolonged cash conversion cycles, for instance. Once these drivers have been identified, it will become easy for you to manage the area of impact and drive positive outcomes. - Granular Level

Drilling down further, your focus should now reach the tactical level. The idea here is to draw a plan of action to implement the necessary changes distilled from steps 1 and 2 above. For example, this could entail determining ideal buffer stock levels for slow-moving goods, shifting stock of a product from a low-demand location to a high-demand location, or identifying ideal inventory levels for cost-effective demand fulfillment.

Never Lose Sight of Impact

No amount of effort and optimization is ever enough if supply chain efficiency doesn’t also reflect in the form of substantial financial benefit for the company. And this is true for enterprises, mid-sized companies and even boutiques.

At a bare minimum, you should be able to:

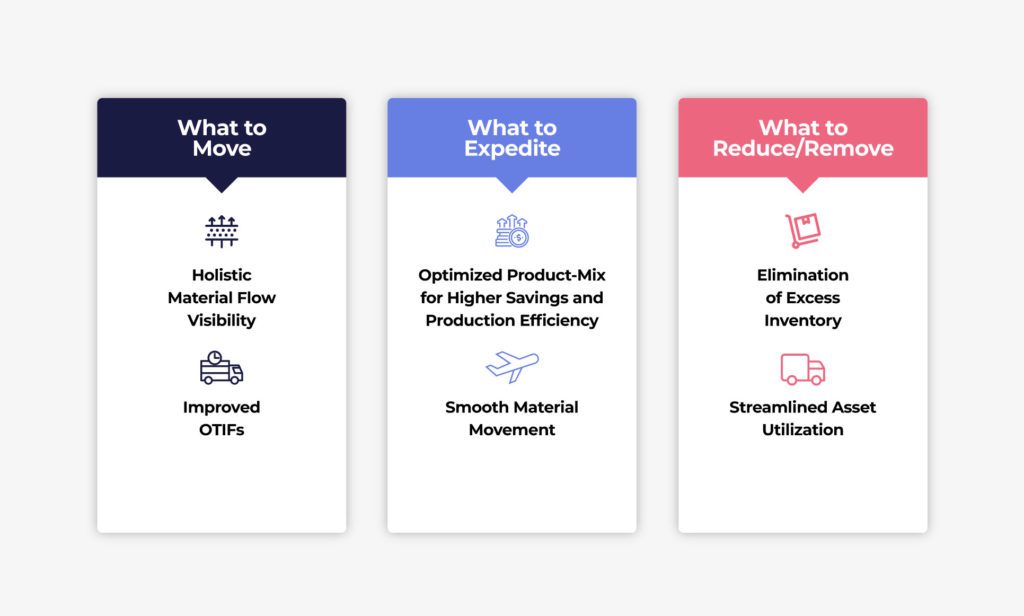

- Compare the net profit contributions of all major functional areas in your supply chain – such as demand, inventory, product mix, process/production, and distribution – taking into account all interdependencies and constraints

- Rank impact areas by impact/priority of potential improvements

- Ascertain the potential net profit impact in each impact area

- Determine the overall expected net profit impact following the implementation of recommended actions

With this level of visibility, you can rapidly identify improvement areas that can drive maximum revenue and profitability.

For example, effective product portfolio optimization can ensure that only those products that can generate a positive cash flow are produced – with all resources and processes prioritized for them.

The Key to Supply Chain Efficiency is a Holistic Approach to Cost Reduction

The role of supply chains in businesses is more strategic than ever, and cost reduction in this area is critical to continued success.

However, with global supply chains becoming more complex, there is an urgent need for holistic solutions that focus on meaningful business outcomes, rather than attempting to find point solutions to cut costs.

“As an outcome-focused supply chain leader, you should therefore shift away from one-off cost reductions and instead adopt a more cross-functional approach so that you can achieve recurring savings.”

Here’s the thing: A volatile market and ever-changing supply demand dynamics make the perfect case for ensuring granular visibility and actionability into demand, inventory, and logistics operations.

But most organizations today struggle to acquire this level of visibility and as a result, have little or no control over the impact of disruptive and unpredictable changes in all of these aspects, also directly affecting the overall cash flow.

ThroughPut: End-to-End Supply Chain Visibility and Actionability Solution

ThroughPut’s holistic supply chain visibility & actionability solution operates through a financial lens and offers end-to-end visibility and actionability that helps supply chain planners in multiple ways by:

- Accurately predicting and eliminating bottlenecks in productivity

- Safeguarding and enhancing margins and share of wallet

- Ensuring continued profitability and growth by meeting customer demand

If you wish to contact us to understand how ThroughPut can help you in reducing supply chain costs and increasing efficiencies across the value chain, do reach us here for a quick demo.