Retail Supply Chain Management – Moving to the Next Normal

When the COVID-19 pandemic struck as a major global humanitarian crisis, the retail world came across challenges it had never faced before. Demand for essentials rose ten-fold and consumer shopping patterns changed almost overnight and probably forever.

The pandemic exposed the breaches in the ability of retailers to reduce supply chain imbalances and offer an omnichannel customer experience, among other challenges of the retail supply chain.

In this new retail world, you need real-time visibility across the value chain so that you can fulfill your consumers’ expectations as well as enhance customer experiences.

Maintaining consistency in the overall customer experience will involve the smooth movement of materials through the chain, eliminating bottlenecks as they arise, getting comprehensive supply chain visibility, and more.

Retailers need to combine online and offline data and put data-driven retail supply chain processes in place to understand what products to stock, how much to stock, and how to distribute them through different channels so consumers can have easy and fast access.

Retail Supply Chain Management – When your Shoppers Want Free, Fast, and Multiple Deliveries

What is retail supply chain management? In simple terms, retail supply chain management is the process of managing all the steps involved in the supply chain of retail organizations.

But how is it different from any other supply chain management? The entire process is optimized to maximize both speed and productivity.

As retailers struggle to meet fast and quality delivery expectations, retail supply chain management can help them optimize each step of the process, right from obtaining the raw materials to making the product to delivering it to the consumer’s doorstep.

You may argue that small retail businesses don’t need a supply chain to meet consumer expectations but in a market that’s constantly evolving, you may need insights into a lot of things.

The Many Woes of Retail Supply Chain Management

The stakes for the retailers today are very high. Growing pains like delayed delivery times, high fulfillment costs, and the inability to find efficient and cost-effective shipping options can be overwhelming.

Let us look at the challenges of a retail supply chain management.

How to Meet Regular Consumer Demands and Expectations?

One of the biggest challenges that retailers face today is keeping track of the changing consumer demands.

You may have a dedicated consumer base but as the needs of the consumers are evolving, they’re choosing convenience over retailer familiarity and will switch to your competitor if they are better equipped to accommodate them.

One of the many challenges faced by retailers in the post-pandemic world is irregular demand. Consumer behavior has changed across several aspects, including shopping trip frequency, selection of channels, category consumptions, brand preference, and consumption of media.

Along with the forecasts for virus containment and economic recovery these changes are essential for forming retail strategies.

At the beginning of the pandemic, the demand for items like cleaning supplies like tissue paper rolls, readymade snacks or ready-to-cook food items, vitamins, supplements, and others was high.

More than immediate consumption, the demand for these products rose for pantry load to prepare for the lockdowns across the world.

But post-crisis and once the lockdowns were lifted, the demand for these products went back to normal. These drastic shifts in demand prompted the question, where and how consumers are shopping? According to the trends, there was a rapid shift from in-store purchasing to e-commerce.

Retail businesses that could monitor this change and quickly respond online made huge profits but most businesses that weren’t prepared for the change due to lack of insights and forecasts, lost a lot of business during the pandemic.

How to Get Essentials Delivered Where and When Needed?

As the COVID-19 crisis intensified, the demand for e-commerce propelled high while in-store shopping declined. Online sales spiked by 93% in 2020 and are still likely to grow in the post-pandemic world.

This behavior change is likely permanent and while larger retail chains have accelerated transformation, smaller businesses still have to catch up with the new trend.

With most physical shops closed and the hesitancy among shoppers to visit these shops, the trend has shifted to home delivery of essentials and while most retailers have accelerated the transformation of their supply chains, it still remains a huge challenge for the retail business.

Distribution Complexities

With the development of the online marketplace, retailers now have more channels for the distribution of their products. While some products can be sold from your brick and mortar stores, others can be distributed via your company website or other third-party online or physical retailers.

Many consumers enjoy the in-store experience while others may expect to be able to place orders online and receive them as soon as possible.

To maintain this balance of distribution and managing supply chain logistics to maximize the opportunities through every channel, you need extensive planning and flexibility.

Stock Keeping Unit (SKU) Management

SKU management, in simple terms, encompasses keeping track of products digitally. SKU management essentially helps you keep track of your inventory.

Without proper SKU management, it is difficult for retailers to detect cyclical sales cycles, determine best and worst products, identify outdated items, or manage inventory turnover.

Product Mix Optimization

Retailers often face the issue of creating an ideal product assortment policy to maximize sales. This issue becomes more compelling when a retailer needs to broaden its reach to a larger market or different geography.

As a retailer, you need to understand the key store parameters that determine sales and to put ideal assortment policies in place.

Stock Management and Replenishment Strategy

Another crucial challenge for retailers involves keeping track of their stock. To keep up with the competition in the ever-evolving market, you need to be able to have end-to-end visibility into your entire supply chain along with real-time inventory data.

With proper demand forecasting, you can significantly improve your inventory replenishment strategies.

Optimal Distribution

Many retailers tend to buy first and then hope to figure things out later. This often leads to mismanaged workflows and manual, error-prone processes that disrupt the optimal distribution of products to different channels, affecting profits.

With proper technology and supply chain review processes, you can achieve optimal distribution based on real-time data.

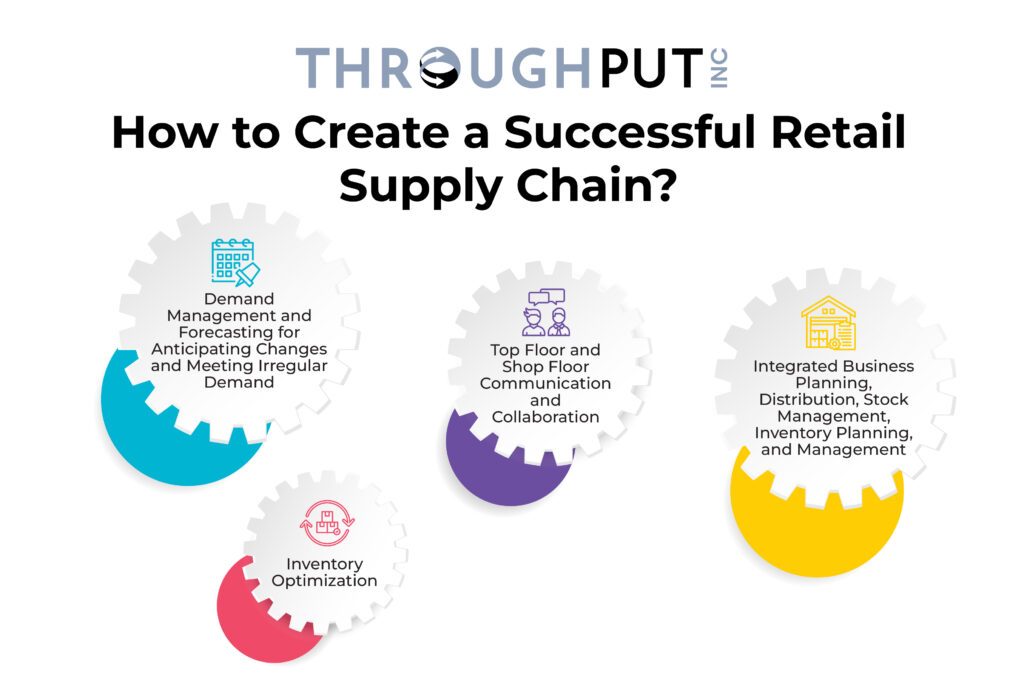

How to Create a Successful Retail Supply Chain Management?

There are several key elements of successful retail supply chain management. Let us take a look.

Demand Management and Forecasting for Anticipating Changes and Meeting Irregular Demand

It’s not new information that retailers need to keep track of market demand to meet consumer expectations. But in the current market ravaged by the pandemic, just keeping track of current demand is not enough.

An efficient retail supply chain management should have proper demand planning, forecasting, and management strategies and tools.

From looking at historical data to incorporating market and consumer research, resource and capacity planning, and more, you should be able to effectively manage demand and anticipate the changes before they happen.

With proper demand forecasting, you can not only anticipate what your shoppers are looking for but also how and where they’re looking for the products.

Inventory Optimization

With advanced analytics and Artificial Intelligence (AI) at your disposal, you can obtain insights into what and how much is likely to sell where. These insights can help you create a unique inventory profile for items allowing you to estimate the ideal distribution of items and predict possible fluctuations in demand.

These insights further help you avoid out-of-stock situations and machine learning algorithms can help you get demand forecasts for specific items to optimize your inventory further.

Top Floor and Shop Floor Communication and Collaboration

Another important element of a successful retail supply chain is proper communication and collaboration between your top floor and shop floor staff. Ineffective and dispersed communication can often lead to losses.

With a bird’s-eye view of your shop floor, you can make complex communication of workstations, departments, and project groups more streamlined.

Disruptions on the shop floor often occur when the information required at locations reaches too slowly, incomplete, or not at all, especially at locations where such information is needed the most.

Using a strategic approach or smart communication, using emerging technologies like Artificial Intelligence, you can easily overcome this challenge.

Integrated Business Planning, Distribution, Stock Management, Inventory Planning, and Management

Retailers need to take an integrated approach to better fulfill customer expectations. You must unify all your customer touchpoints across stores and digital devices, reinforced by an in-built data model, integrated processes, and systems across the retail supply chain.

By integrating data for order management and consumer service, you can ensure that all customer interactions are personalized and relevant across all channels. With integrated business planning, you get an opportunity to innovate so that sales go up and costs go down.

It also allows you to manage your product distribution channels, allocate resources productively, keep track of inventory levels, and most importantly, helps you track and predict new trends so that you have enough time to respond to rapidly shifting demand and turn challenges into opportunities.

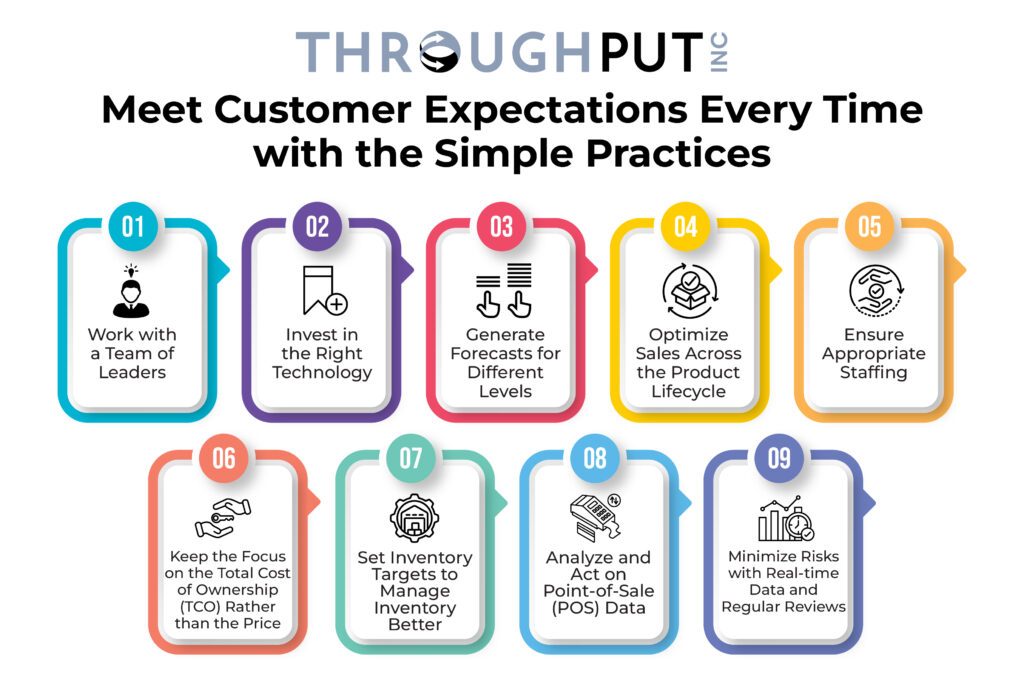

Meet Customer Expectations Every Time with the Simple Practices

Some best practices in retail supply chain management will help you navigate the domain better.

1. Work with a Team of Leaders

Identify supply chain leaders from your internal teams and form a small team to identify and mitigate supply chain issues as they arise. This will enable two-way communication and create an organized supply chain.

2. Invest in the Right Technology

Focus on ‘right’ technology that will benefit your business. You don’t need overly complicated systems to make your processes more complex.

You need a system that can help you predict demand, analyze patterns, suggest the best sources of supply, enable decision-making based on real-time data, mitigate bottlenecks, and more.

3. Generate Forecasts for Different Levels

Predict sales for various SKUs while forecasting at the product, family, store, and customer levels with emerging technologies.

4. Optimize Sales Across the Product Lifecycle

Keep track of your raw materials from procurement to sell-off with advanced insights that will help you make faster decisions and speed up in-season replenishment.

5. Ensure Appropriate Staffing

Your staff needs to understand and get trained for the ‘big picture’ so the processes and workflows can run smoothly from top to bottom. Make sure your staff is well-informed and well-trained in new technologies when you introduce them.

6. Keep the Focus on the Total Cost of Ownership (TCO) Rather than the Price

It’s easy to focus on the price when choosing a supplier, especially if it’s a small business. But with strategic sourcing, you can instead focus on the total cost of ownership (TCO) of a product or service, which will help you gain long-term success instead of short-term gains.

7. Set Inventory Targets to Manage Inventory Better

As a retailer, you need to set a balance of trade-off between anticipated service levels and inventory investments.

With proper demand sensing tools, you can set inventory targets based on order quantity rules and safety stocks, which helps you enhance customer service while keeping the supply chain in check.

8. Analyze and Act on Point-of-Sale (POS) Data

Analyze different demand signals to improve the accuracy of your demand planning. Leverage POS data to understand what sells and what doesn’t.

9. Minimize Risks with Real-time Data and Regular Reviews

Retailers must make it a point to meet the supply chain team regularly and review procedures and policies to ensure compliance, supply chain efficiency, and relevance.

Using real-time data about policies and procedures, you can avoid process bottlenecks and streamline operations. It also helps you minimize the risk of theft and fraud.

Move ahead with technology – choose ‘right’

As pointed out earlier, a successful retail supply chain will need the ‘right’ technology to function. While many big names in the market can easily have you confused, you need to assess your business priorities and needs to make the right choice and build a smart supply chain.

Here are some points to look for while choosing technology for your retail supply chain:

Advanced Analytics

At the most basic level, your supply chain technology should be able to apply mathematics, statistics, predictive modeling, and Machine Learning (ML) techniques to find meaningful patterns through the heaps of data produced by enterprise systems and external sources.

While analyzing both structured and unstructured data sources, advanced analytics will help you conclude demand, inventory, production, and distribution operations so you can make informed business decisions and act swiftly.

Asset Tracking and Management

One of the important aspects of technology in the retail supply chain involves tracking assets and managing them through their lifecycle.

With technologies like Radio-Frequency Identification Devices (RFID) tags and Internet of Things (IoT), you can easily track every product or asset and make decisions based on up-to-date data.

Fully Integrated retail Supply Chain Management Solution

With a fully integrated retail supply chain management solution, retailers can optimize their operations and make accurate decisions based on real-time data. These fully integrated solutions help you set and meet realistic goals by defining the roadmap with a data-driven approach.

They also prompt you to categorize and flag out-of-control processes and optimize the efficiency of your chain. Using AI-powered data, these solutions help you dig deeper into the root cause of problems.

You can identify out-of-norm events in real-time as the system highlights deviations in performance, defines root causes, and prescribes solutions.

You also get a bird’s-eye view with key insights on a single platform and get end-to-end visibility into your chain to stay ahead of issues. These integrated solutions help you assess your key operational metrics and predict revenue, profitability, cost, and ROI.

Benefits of Adding ELI Intelligence to Your Retail Supply Chain

With ThroughPut’s AI supply chain intelligence software, you can leverage AI-powered supply chain intelligence to gain comprehensive visibility right from your upstream to downstream operations.

Right from elevating your inventory turnover to reducing shipping costs and other expenses, ELI helps you create a smart retail supply chain that helps you achieve your business goals.

With features like demand sensing, constraint management, financial management, logistics management, capacity management, and more, ThroughPut AI helps you reduce bottlenecks and increase your productivity and profits.

Need more information about ThroughPut AI? Schedule a demo right away!